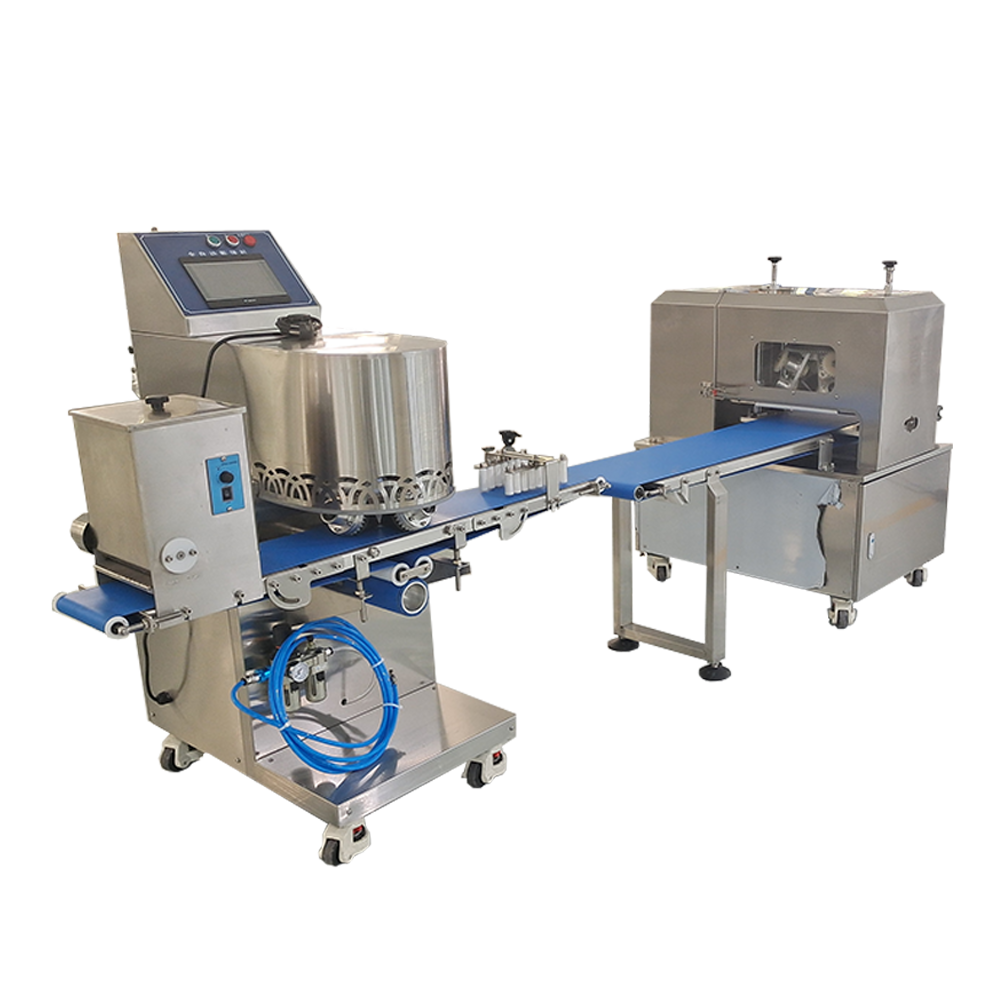

pretzel making equipment

Pretzel making equipment represents a sophisticated blend of engineering and culinary technology designed to produce perfectly twisted pretzels with consistency and efficiency. This advanced machinery encompasses a complete production line, featuring automated dough mixing systems, extrusion units, twisting mechanisms, and precise baking controls. The equipment utilizes state-of-the-art PLC controls that ensure accurate temperature regulation, timing, and shape formation throughout the production process. The dough mixing component incorporates high-performance motors and specialized mixing blades that achieve optimal dough consistency, while the extrusion system maintains uniform dough thickness and portion control. The signature pretzel twist is achieved through an innovative mechanical twisting mechanism that replicates the traditional hand-twisting motion with remarkable precision. The equipment also features conveyor systems with adjustable speeds, allowing for customized production rates and seamless movement through various processing stages, from alkaline bath treatment to baking. Modern pretzel making equipment can produce anywhere from 1,000 to 5,000 pretzels per hour, making it ideal for both medium-scale bakeries and large industrial operations.