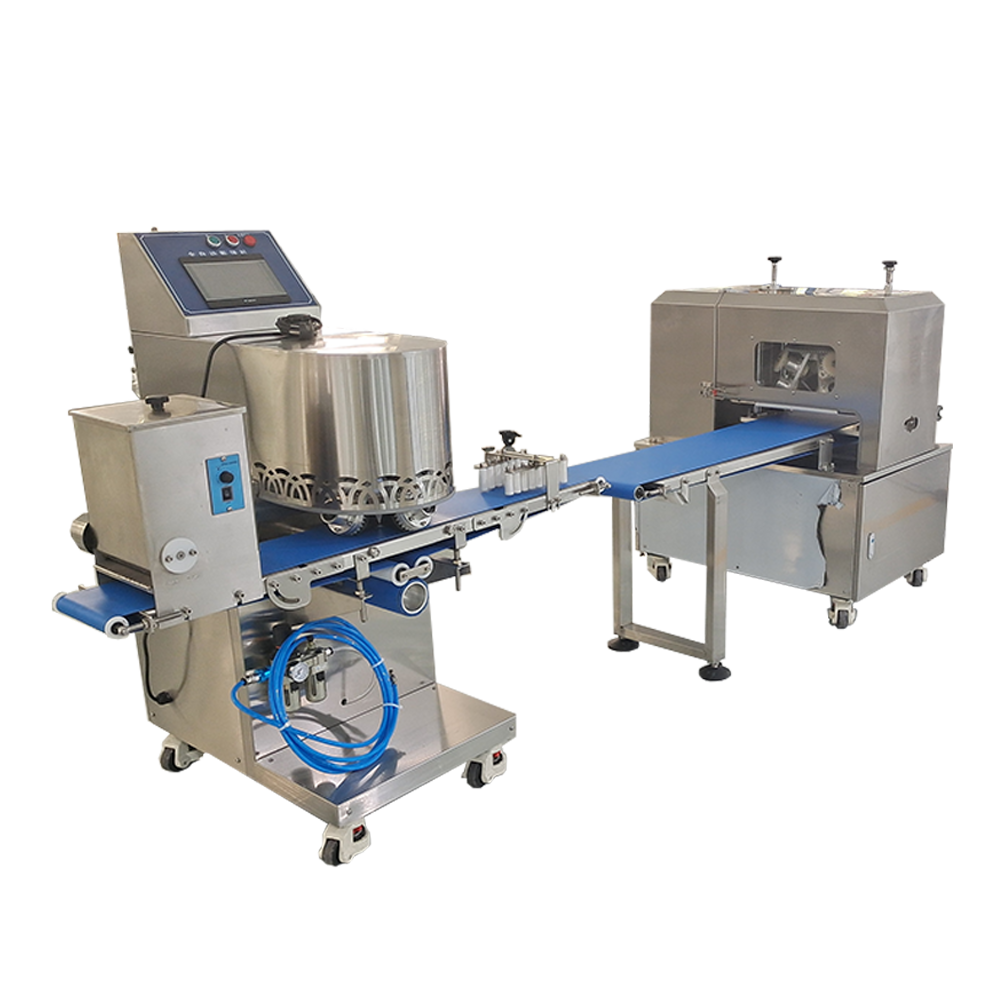

commercial roti maker machine

The commercial roti maker machine represents a significant advancement in automated food preparation technology, designed to streamline the production of consistent, high-quality rotis at scale. This innovative equipment combines precision engineering with user-friendly operation to deliver perfectly rounded, evenly cooked flatbreads. The machine features a sophisticated temperature control system that maintains optimal cooking conditions, ensuring each roti is cooked to perfection with the ideal thickness and texture. Its automated pressing mechanism applies uniform pressure to create rotis of consistent size and shape, while the non-stick cooking surfaces prevent sticking and facilitate easy cleaning. The machine can handle various types of flour and dough compositions, making it versatile for different roti varieties. With production capabilities ranging from 800 to 1200 rotis per hour, it significantly reduces labor costs and increases efficiency in commercial kitchens. The machine incorporates safety features such as emergency shut-off switches and thermal protection systems, ensuring safe operation in busy kitchen environments. Additionally, its compact design optimizes kitchen space utilization while maintaining high output capacity.