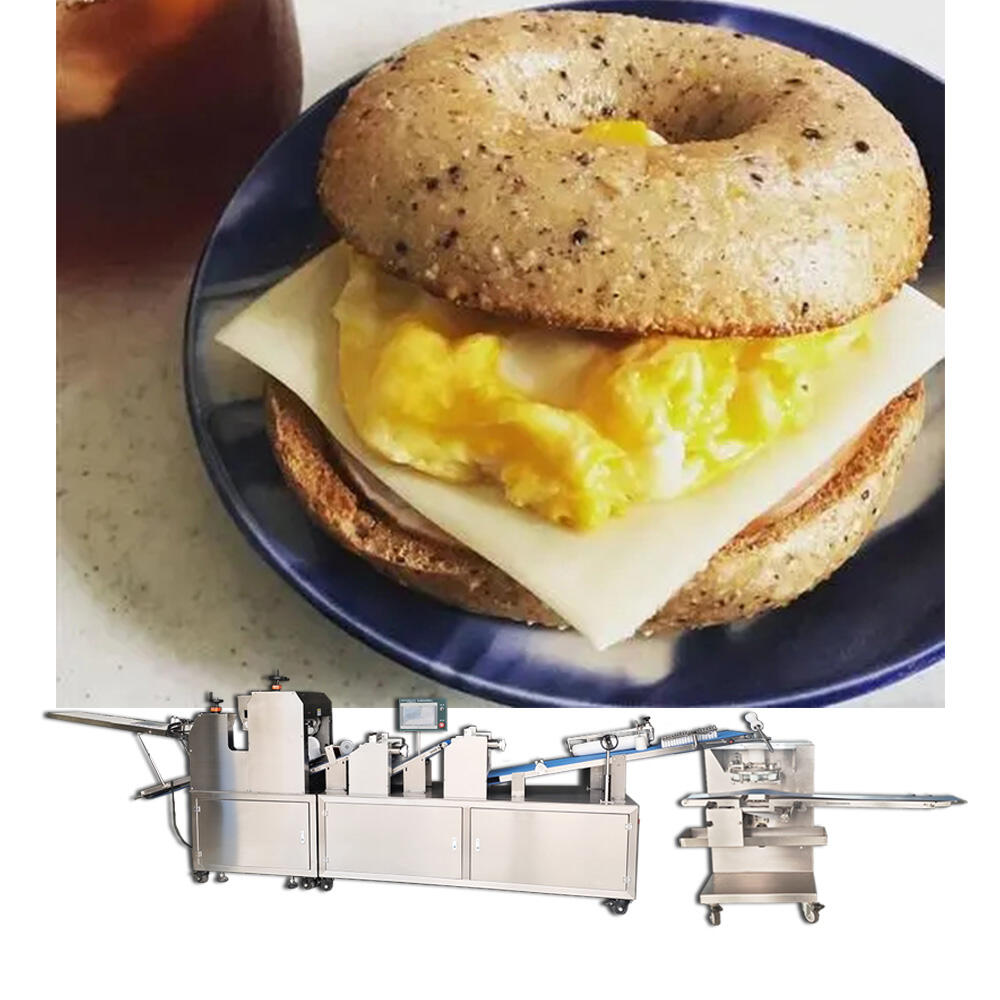

bagel production line

A bagel production line represents a sophisticated automated system designed to streamline the manufacturing of perfectly formed bagels with consistency and efficiency. This comprehensive system integrates multiple stations that handle everything from dough mixing and dividing to shaping, proofing, boiling, and baking. The line begins with precise ingredient measurements and mixing, ensuring proper gluten development. The dough then moves through an automated divider that portions it into uniform pieces, followed by a rounding mechanism that creates the characteristic bagel shape. A key technological feature is the computer-controlled proofing chamber, where temperature and humidity are carefully regulated to achieve optimal dough development. The unique boiling station, equipped with automated conveyor systems, ensures each bagel achieves its distinctive chewy texture and glossy exterior. The final baking phase occurs in industrial-grade ovens with multiple temperature zones for perfect crust formation. Modern bagel production lines incorporate smart sensors and digital controls that monitor every aspect of production, from dough consistency to baking parameters, allowing for real-time adjustments and quality maintenance. This automated system can produce thousands of bagels per hour while maintaining consistent size, shape, and quality throughout the entire process.