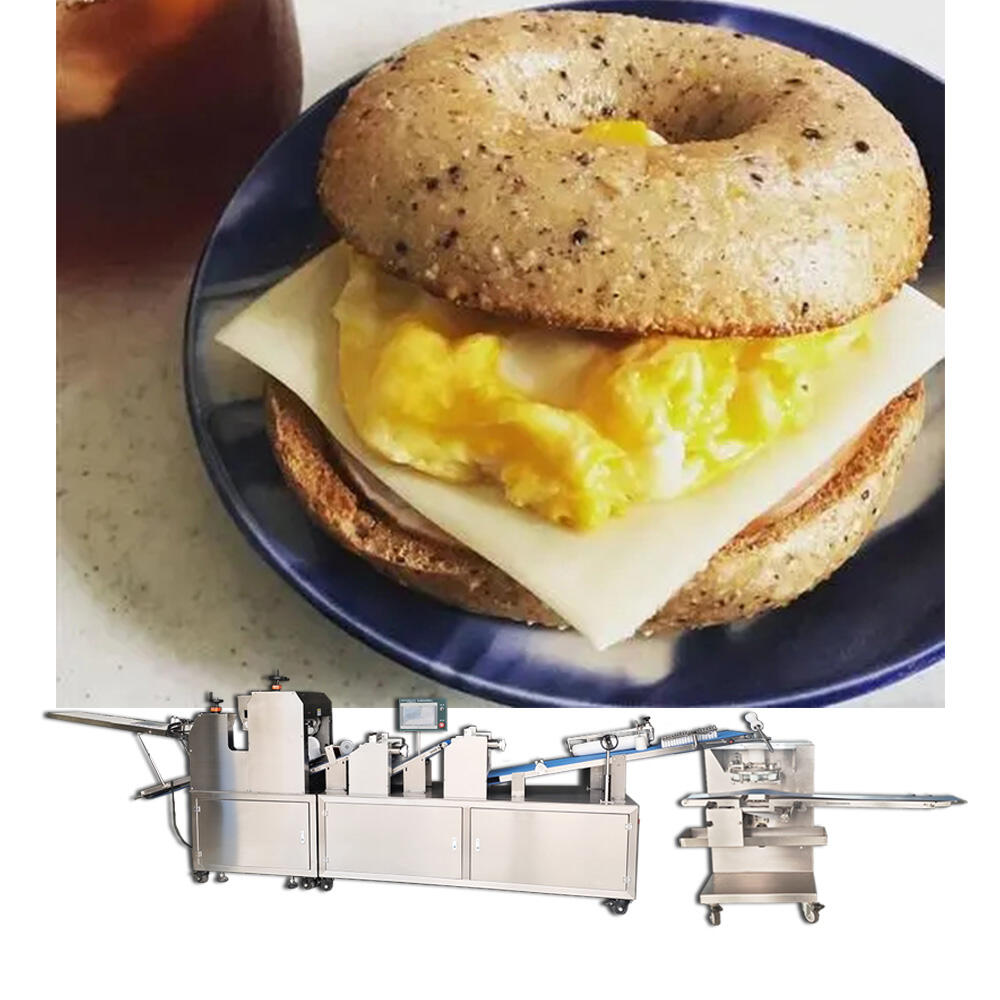

bagel making machine

A bagel making machine is a sophisticated piece of commercial equipment designed to streamline and automate the traditional bagel production process. This innovative device combines multiple functions including mixing, dividing, forming, proofing, and baking capabilities all in one efficient system. The machine features precision-controlled temperature settings and automated timing mechanisms to ensure consistent results with every batch. Advanced models incorporate digital interfaces for precise control over various parameters such as dough consistency, size uniformity, and baking conditions. The equipment typically includes a high-capacity mixing bowl with powerful motors capable of handling dense bagel dough, automated portioning systems that ensure uniform size and weight, and specialized forming mechanisms that create the distinctive bagel shape while maintaining the proper texture. Modern bagel making machines often feature energy-efficient heating elements and innovative steam injection systems that create the characteristic glossy exterior while maintaining a chewy interior. These machines can produce hundreds of bagels per hour, making them ideal for both medium-sized bakeries and large-scale commercial operations. The equipment is designed with food safety in mind, incorporating stainless steel construction and easily cleanable components that meet strict hygiene standards.