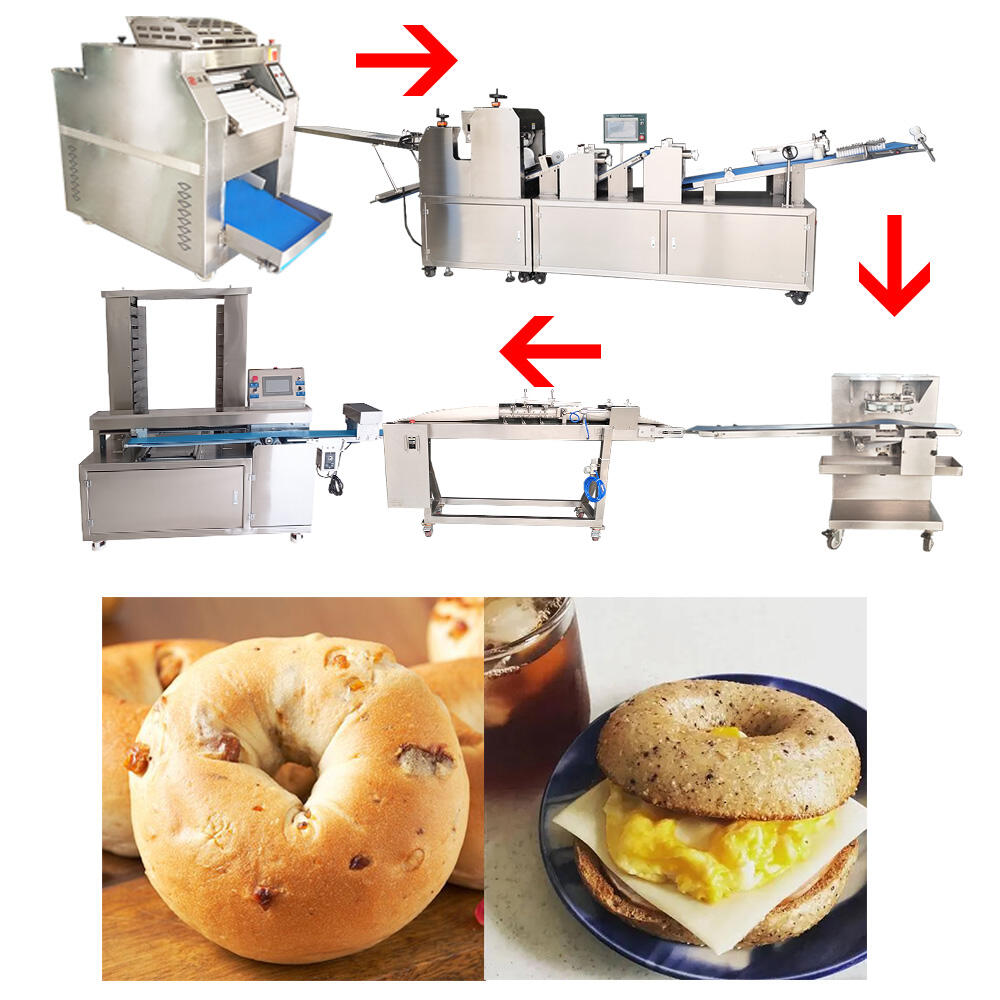

bagel machine

A bagel machine represents a sophisticated piece of commercial bakery equipment designed to streamline the traditional bagel-making process. This automated system combines precision engineering with modern technology to handle multiple stages of bagel production, from dough formation to the final baking process. The machine features a programmable control panel that allows operators to adjust various parameters including mixing time, proofing conditions, and baking temperature. Its robust stainless steel construction ensures durability and compliance with food safety standards, while the modular design facilitates easy cleaning and maintenance. The system typically includes an automated mixer, divider, and former that creates consistently sized dough portions, followed by a proofing chamber that provides optimal conditions for dough development. The integrated boiling system, a crucial component for achieving authentic bagel texture, automatically manages water temperature and cooking time. The final baking stage occurs in a precision-controlled oven chamber that ensures even heat distribution for perfect results. Modern bagel machines can produce hundreds of bagels per hour while maintaining consistent quality and reducing labor costs significantly.