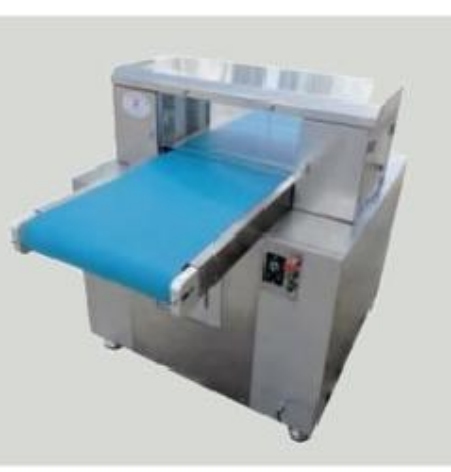

ultrasonic cake cutting machine

The ultrasonic cake cutting machine represents a revolutionary advancement in food processing technology, combining precision engineering with ultrasonic vibration to deliver superior cutting results. This innovative machine utilizes high-frequency vibrations, typically operating between 20-40 kHz, to create clean, precise cuts through various cake products while maintaining their structural integrity. The system comprises a titanium blade that vibrates ultrasonically, reducing friction and preventing product adhesion during the cutting process. The machine's cutting mechanism is designed to handle a wide range of cake densities and textures, from delicate sponge cakes to dense fruit cakes, without compromising their appearance or texture. Advanced control systems allow operators to adjust cutting parameters, including blade amplitude and cutting speed, ensuring optimal results for different product types. The machine features an automated feed system that synchronizes with the ultrasonic cutting action, enabling continuous operation for high-volume production environments. Safety features include emergency stop mechanisms and protective guards, while the hygienic design facilitates easy cleaning and maintenance. The ultrasonic cake cutting machine's versatility extends to various cutting patterns, including horizontal layers, vertical portions, and custom shapes, making it suitable for both industrial bakeries and specialty cake manufacturers.