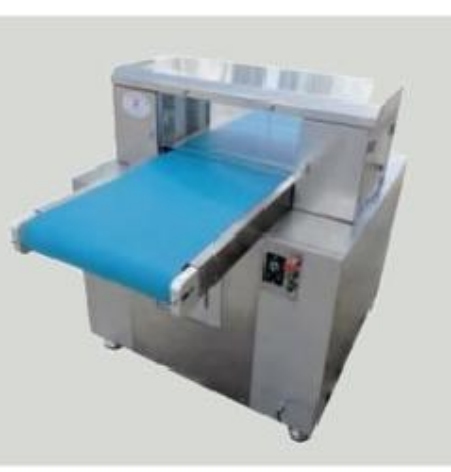

cake slicer machine

The cake slicer machine represents a revolutionary advancement in bakery automation technology, designed to deliver precise and uniform cake cutting results with exceptional efficiency. This sophisticated equipment utilizes high-grade stainless steel blades and advanced positioning systems to achieve perfectly portioned slices every time. The machine features adjustable cutting parameters, allowing operators to customize slice thickness and patterns according to specific requirements. Whether handling round, square, or rectangular cakes, the versatile design accommodates various cake sizes and shapes. The automated system incorporates safety features including blade guards and emergency stop mechanisms, ensuring operator protection while maintaining optimal performance. Advanced sensors detect cake density and texture, automatically adjusting cutting pressure and speed for optimal results. The machine's user-friendly interface enables quick programming of cutting patterns, while its efficient design minimizes cake waste and maximizes yield. Built with durability in mind, the cake slicer machine features easy-to-clean components and requires minimal maintenance, making it an ideal solution for high-volume bakeries, restaurants, and food service operations.