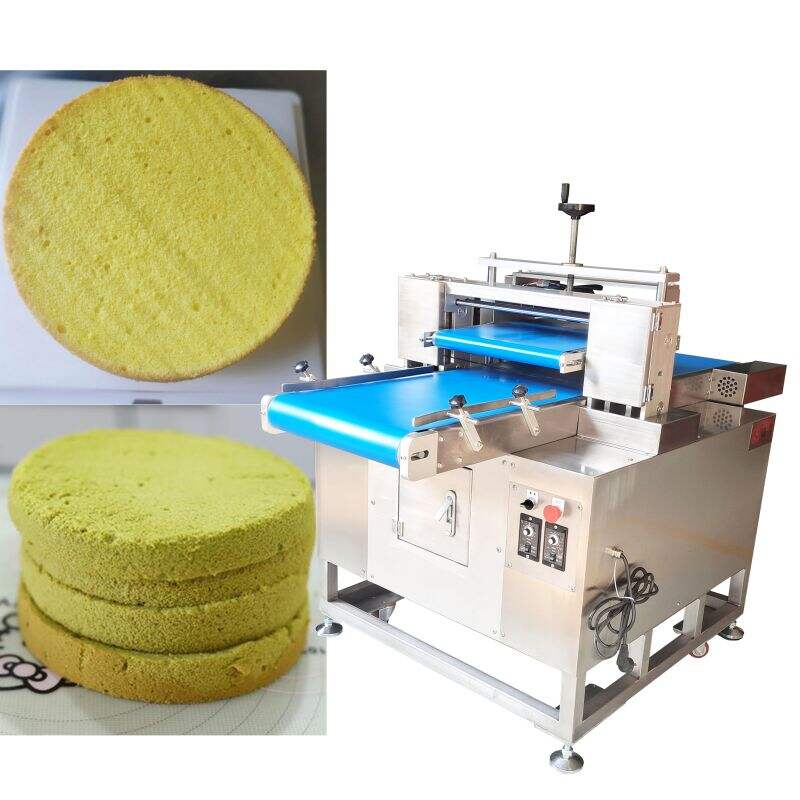

cake cutting machine

The cake cutting machine represents a revolutionary advancement in bakery automation, designed to deliver precise, uniform slices while maximizing efficiency and productivity. This sophisticated equipment utilizes advanced blade technology and adjustable settings to accommodate various cake sizes and textures, ensuring consistent results every time. The machine features a high-grade stainless steel construction, making it both durable and easy to maintain in compliance with food safety standards. Its programmable interface allows operators to select different cutting patterns and slice thicknesses, ranging from traditional wedge cuts to uniform rectangular portions. The machine incorporates safety features including emergency stop buttons and protective guards, ensuring operator safety without compromising performance. With its compact footprint and ergonomic design, it efficiently manages high-volume cutting tasks while occupying minimal counter space. The system includes automated cleaning cycles and removable components for thorough sanitization, addressing crucial hygiene requirements in commercial food preparation environments. Whether handling delicate layer cakes or dense fruit cakes, the machine maintains consistent cutting quality while significantly reducing production time and labor costs.