equipment for a bakery

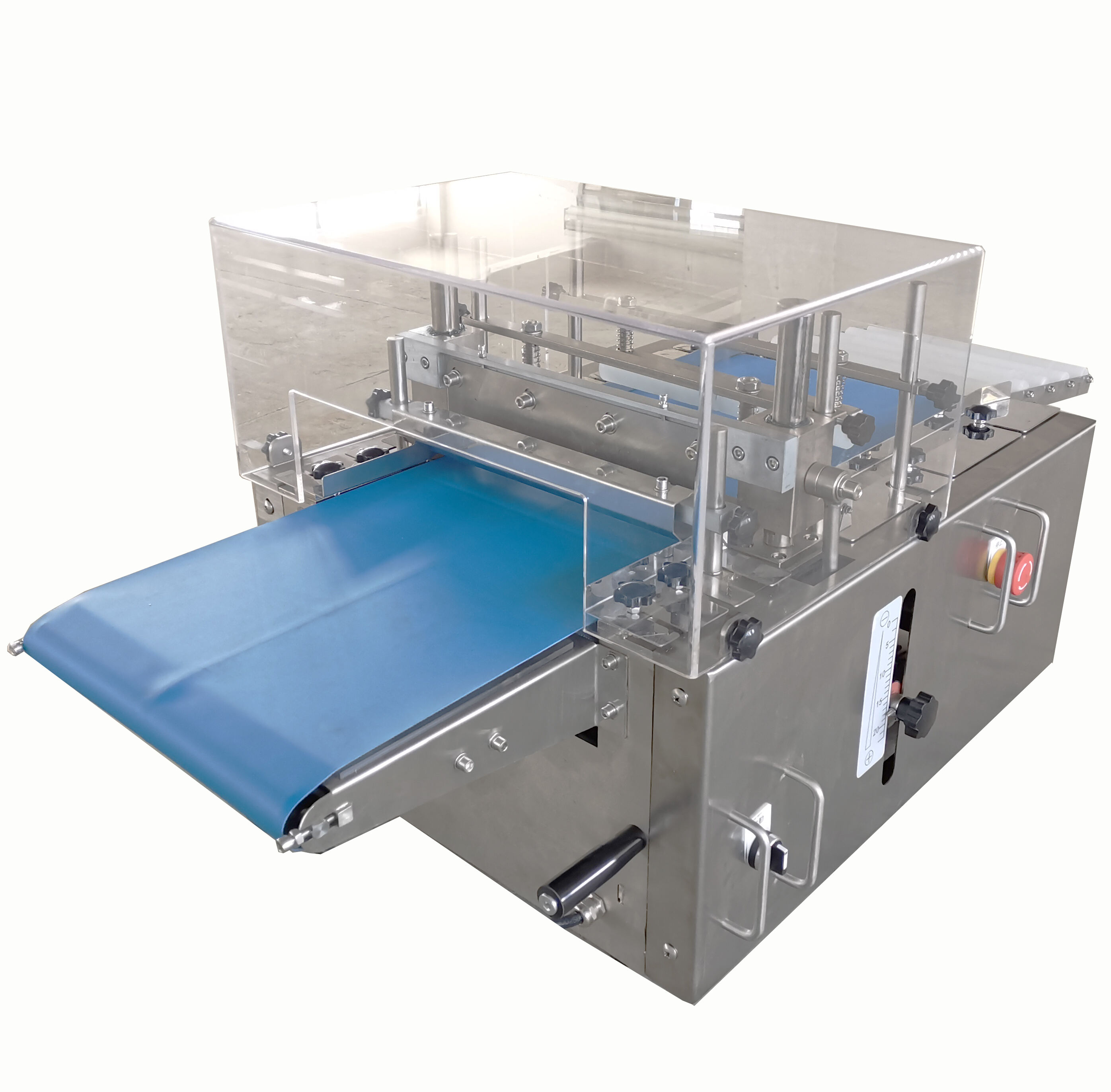

Essential bakery equipment forms the backbone of any successful baking operation, combining functionality with precision to deliver consistent, high quality baked goods. Modern bakery setups typically include commercial ovens with multiple deck configurations, allowing for simultaneous baking at different temperatures. Mixers range from compact 5-quart models to industrial 60-quart systems, featuring variable speed controls and attachments for different dough consistencies. Dough sheeters and dividers automate the portioning process, ensuring uniform size and weight across products. Temperature controlled proofing cabinets maintain optimal conditions for dough fermentation, while specialized cooling racks facilitate proper product finishing. Refrigeration systems, including blast freezers and retarder proofers, provide crucial temperature management throughout the production cycle. Storage solutions encompass ingredient bins, shelving units, and specialized containers designed for both raw materials and finished products. Digital scales and measuring equipment ensure precise ingredient proportions, while workbenches and preparation surfaces provide essential space for hand finishing and decoration. Safety features include emergency shutoffs, thermal protection, and guard rails, all designed to protect operators while maintaining efficient production flow.