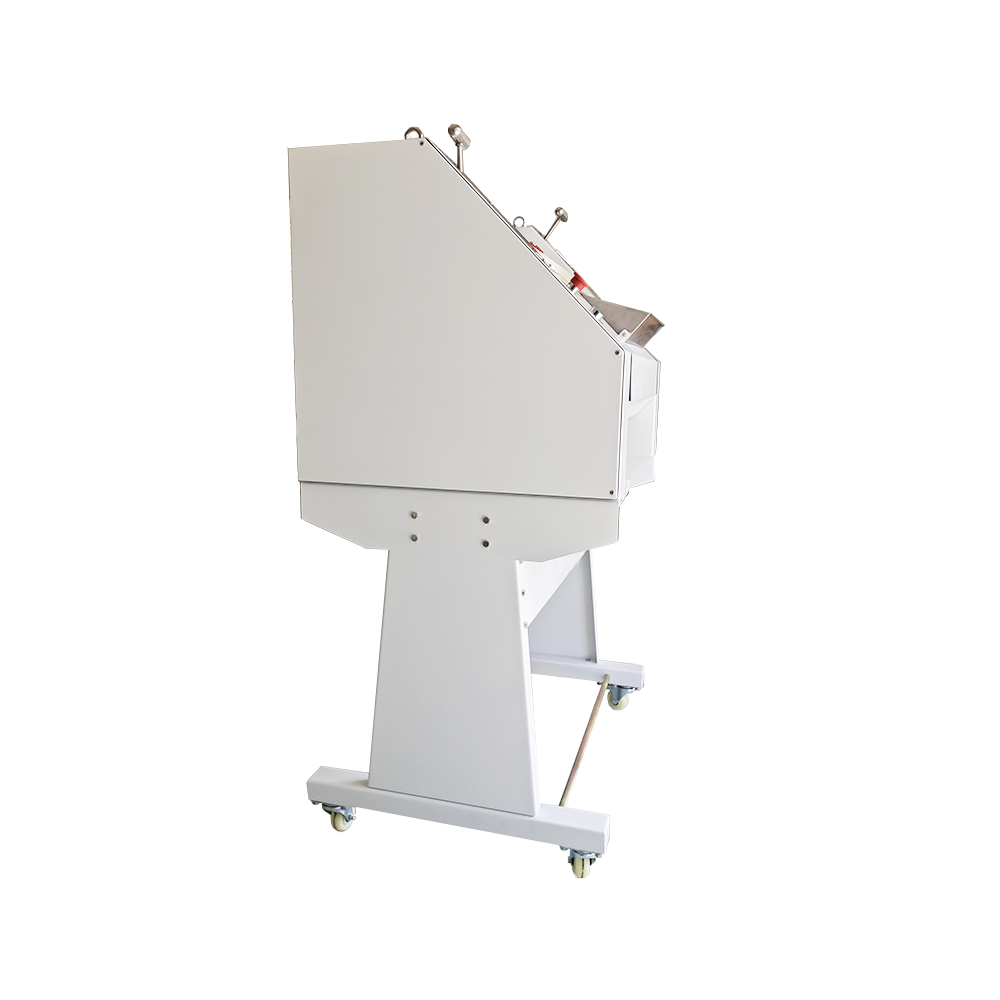

dough roller

A dough roller is an essential piece of commercial bakery equipment designed to efficiently process and shape dough for various baking applications. This versatile machine features adjustable stainless steel rollers that can be precisely calibrated to achieve the desired dough thickness. Modern dough rollers incorporate advanced safety features, including emergency stop buttons and protective guards, ensuring operator safety during operation. The machine's powerful motor drives the rollers at consistent speeds, allowing for uniform dough processing while maintaining the dough's ideal texture and structural integrity. Most models feature dual-direction operation, enabling forward and reverse movement for enhanced control and flexibility. The rollers' non-stick surface treatment prevents dough adhesion and facilitates easy cleaning, while the robust construction ensures durability and longevity in demanding commercial environments. Many units include digital controls for precise thickness adjustment and speed settings, making them suitable for various dough types, from pizza and pastry to bread and pasta. The equipment's compact footprint and ergonomic design maximize workspace efficiency while minimizing operator fatigue during extended use.