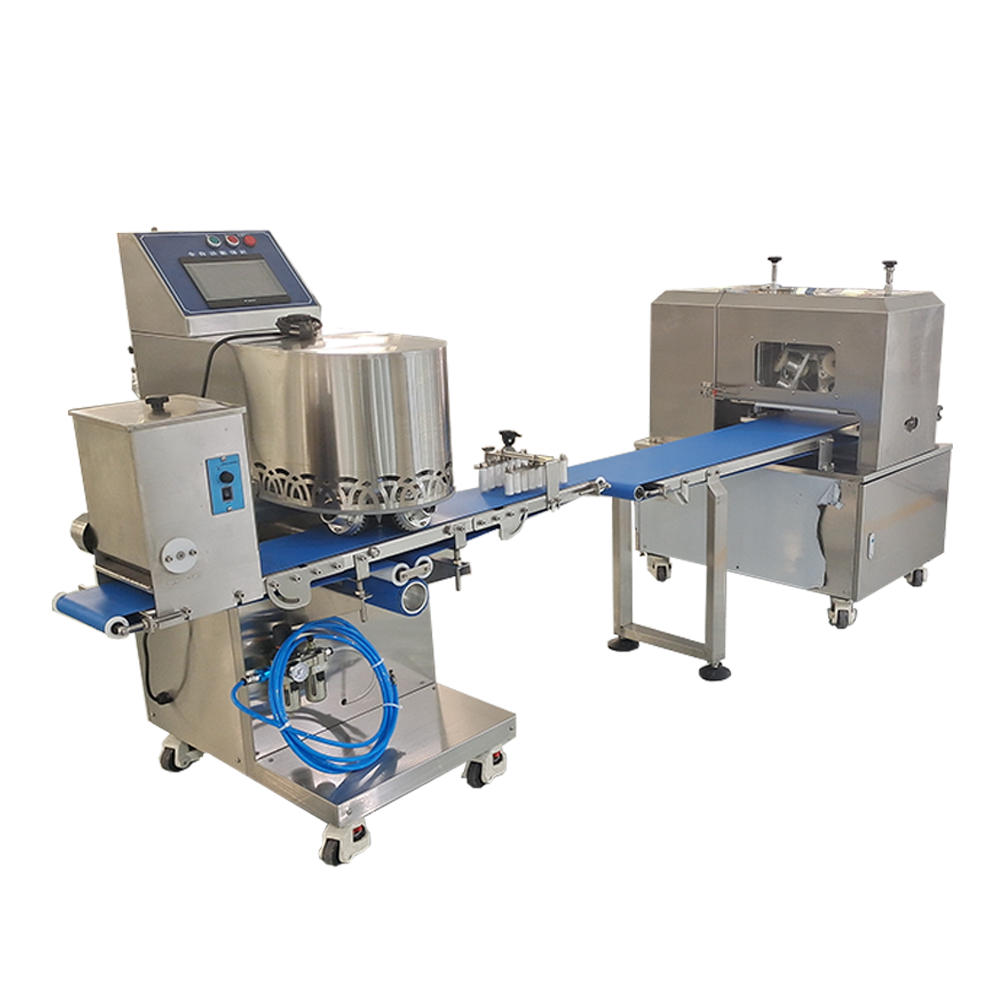

dough sheeter machine

A dough sheeter machine is an essential piece of commercial bakery equipment designed to efficiently flatten and shape dough into uniform sheets. This versatile machine transforms bulk dough into precisely measured sheets with consistent thickness, making it invaluable for producing various baked goods such as croissants, pastries, pizza bases, and bread. The machine features adjustable roller settings that allow bakers to control the final thickness of the dough, ensuring uniformity across all products. Modern dough sheeters are equipped with variable speed controls, safety features, and user-friendly interfaces that streamline the production process. The machine's dual roller system progressively reduces dough thickness while maintaining its structural integrity, preventing overworking that could compromise the final product's texture. Many models include automated belt systems that move the dough through the rollers, reducing manual handling and increasing production efficiency. The technology behind dough sheeters has evolved to incorporate precise calibration systems, ensuring exact thickness measurements down to the millimeter, which is crucial for maintaining product consistency and quality standards.