pizza dough roller

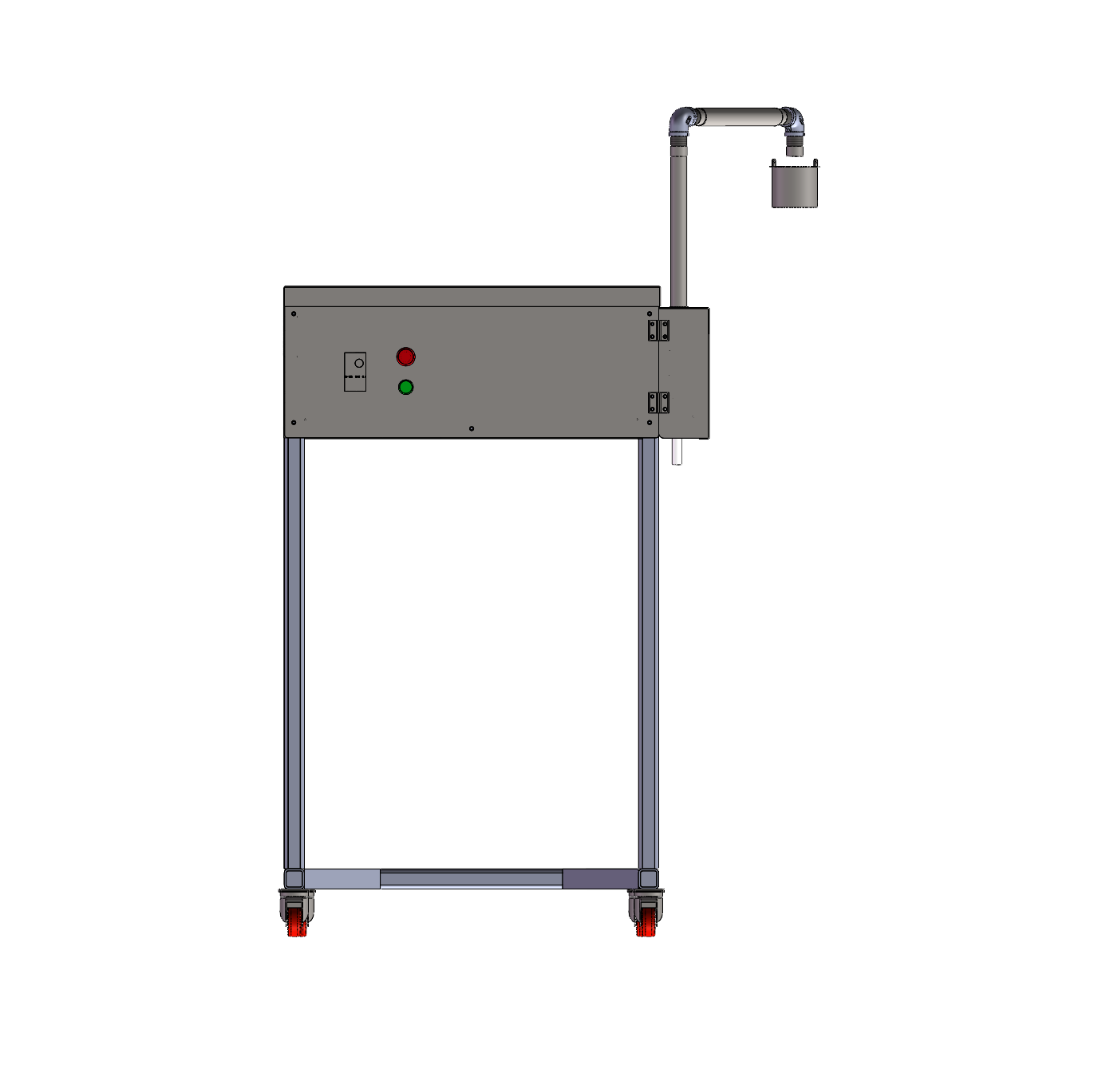

A pizza dough roller is an essential piece of equipment that revolutionizes the way pizzerias and restaurants handle dough preparation. This versatile machine efficiently transforms balls of pizza dough into perfectly shaped, consistent crusts within seconds. The roller features adjustable thickness settings, allowing operators to achieve precise crust dimensions from paper-thin to thick-style pizzas. Modern pizza dough rollers incorporate advanced safety features, including emergency stop buttons and protective guards, ensuring safe operation in busy kitchen environments. The machine's heavy-duty construction, typically featuring stainless steel components, guarantees durability and longevity while meeting strict food safety standards. Most models offer dual-direction rolling capabilities, enabling operators to achieve the ideal dough texture and shape through multiple passes. The non-stick surfaces prevent dough from adhering during the rolling process, while built-in flour dusters maintain optimal dough consistency. These machines can handle various dough types, from traditional pizza to flatbread and specialty crusts, making them invaluable for establishments seeking to expand their menu offerings.