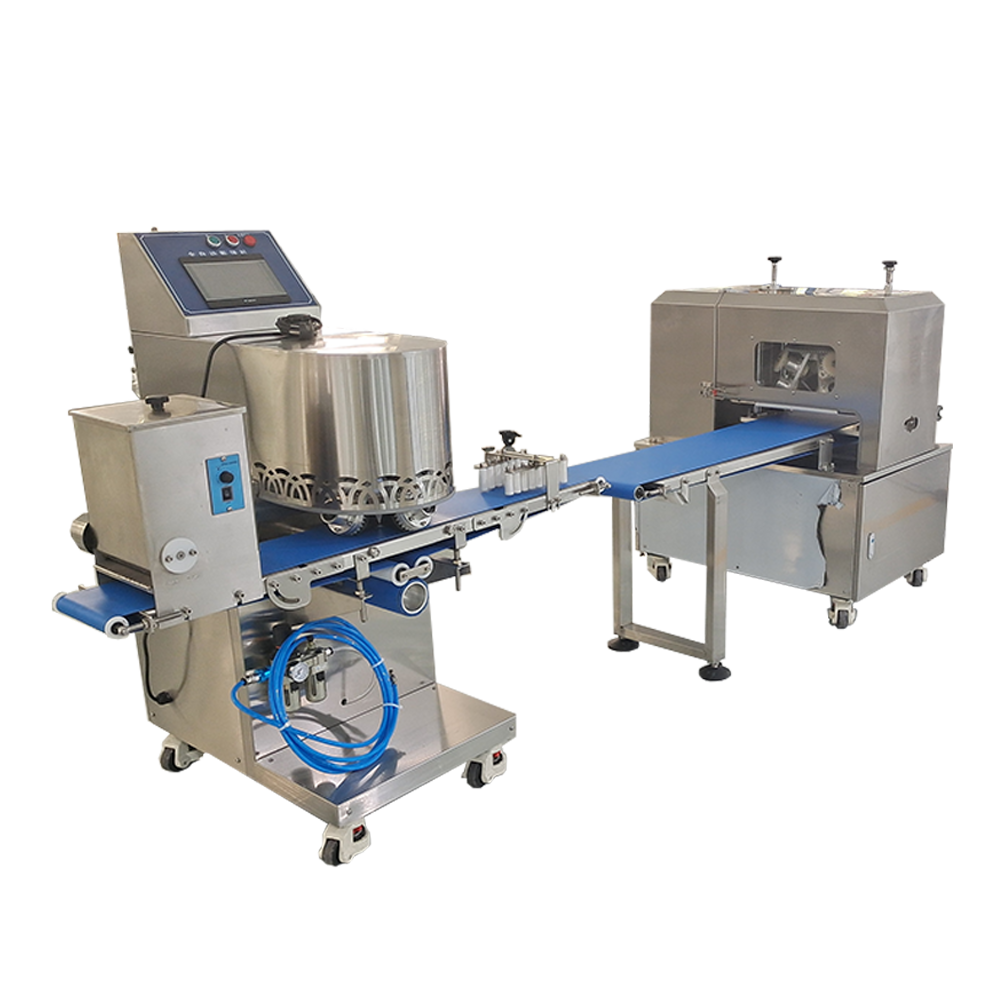

dough divider

A dough divider is an essential piece of bakery equipment designed to precisely portion dough into uniform pieces for consistent baking results. This automated machine combines mechanical precision with advanced technology to streamline the bread-making process. Operating through a series of hydraulic or pneumatic mechanisms, the dough divider efficiently processes large quantities of dough into exact portions, maintaining weight accuracy within minimal tolerances. The machine features adjustable settings for portion size, allowing bakers to produce various products from dinner rolls to large loaves. Modern dough dividers incorporate stainless steel construction for durability and easy cleaning, while non-stick surfaces prevent dough adhesion during processing. The equipment can handle different dough types, from soft to firm consistencies, making it versatile for diverse bakery operations. Advanced models include digital controls for precise weight adjustment and production monitoring, enabling efficient batch processing and reducing material waste. These machines significantly improve production efficiency by eliminating manual division errors and increasing output speed, making them indispensable in commercial bakeries and food service operations.