machines for making biscuits

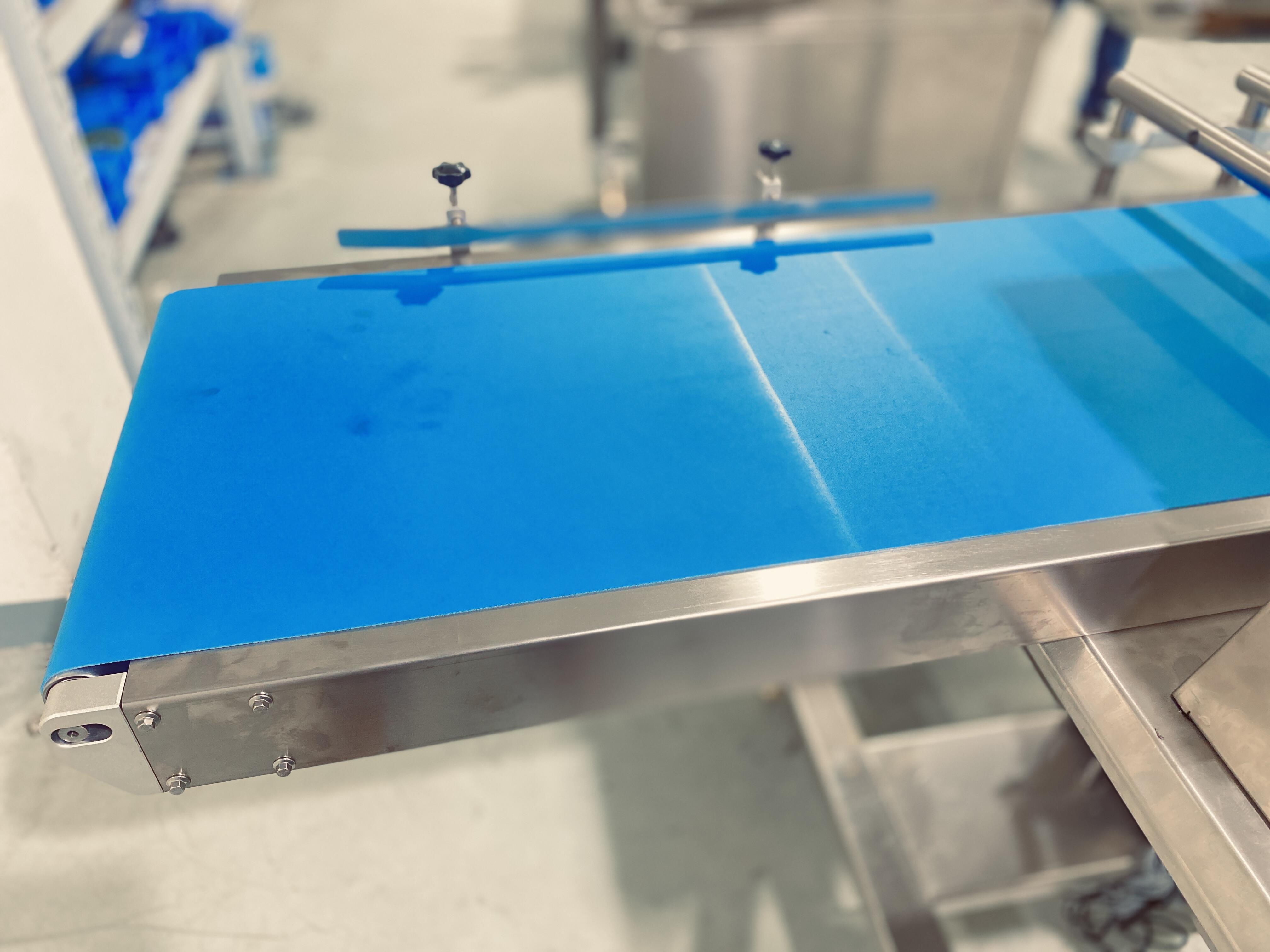

Machines for making biscuits represent cutting-edge technology in the food processing industry, combining precision engineering with automated production capabilities. These sophisticated systems integrate multiple functions including mixing, forming, baking, and cooling processes into a streamlined production line. The machines feature advanced control systems that ensure consistent quality, precise temperature regulation, and uniform baking results. Modern biscuit-making machines are equipped with programmable logic controllers (PLCs) that enable operators to adjust parameters such as dough thickness, baking time, and temperature settings with remarkable accuracy. The equipment typically includes a dough mixer, dough sheeter, rotary moulder or wire cut mechanism, multi-zone baking oven, and cooling conveyor. These machines can handle various types of dough formulations and produce different biscuit styles, from simple cookies to sandwich biscuits. Production capacities range from 100 to 2000 kg per hour, making them suitable for both medium-scale bakeries and large industrial operations. The machines incorporate food-grade stainless steel construction and comply with international hygiene standards, ensuring safe food production. Advanced features often include automatic ingredient dosing systems, recipe management software, and real-time production monitoring capabilities.