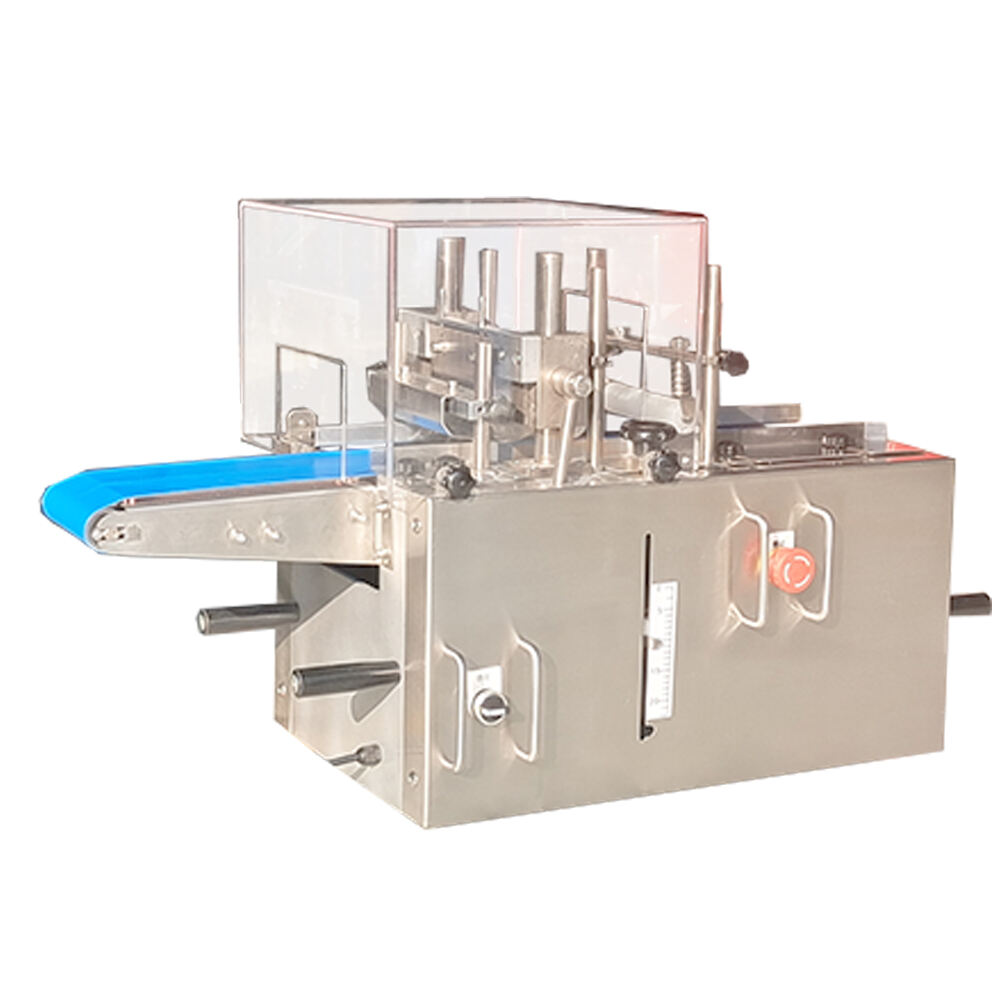

chocolate enrobing

Chocolate enrobing represents a sophisticated industrial process that transforms various confectionery and bakery products by coating them with a uniform layer of tempered chocolate. This advanced technology utilizes a precise system of curtains and belts to ensure complete coverage of products, creating an appealing glossy finish while maintaining consistent quality. The process begins with the careful tempering of chocolate to achieve optimal crystallization, followed by the systematic coating of products as they pass through a flowing curtain of liquid chocolate. The enrobing line typically incorporates temperature-controlled zones, vibrating plates for excess chocolate removal, and cooling tunnels to ensure proper setting. This versatile system can handle a wide range of products, from cookies and wafers to nuts and frozen treats, making it indispensable in modern confectionery production. The technology allows for precise control over coating thickness, temperature parameters, and belt speed, resulting in products with superior appearance and texture. Additionally, the system can accommodate different types of chocolate, including dark, milk, and white varieties, as well as compound coatings, providing manufacturers with extensive production flexibility.