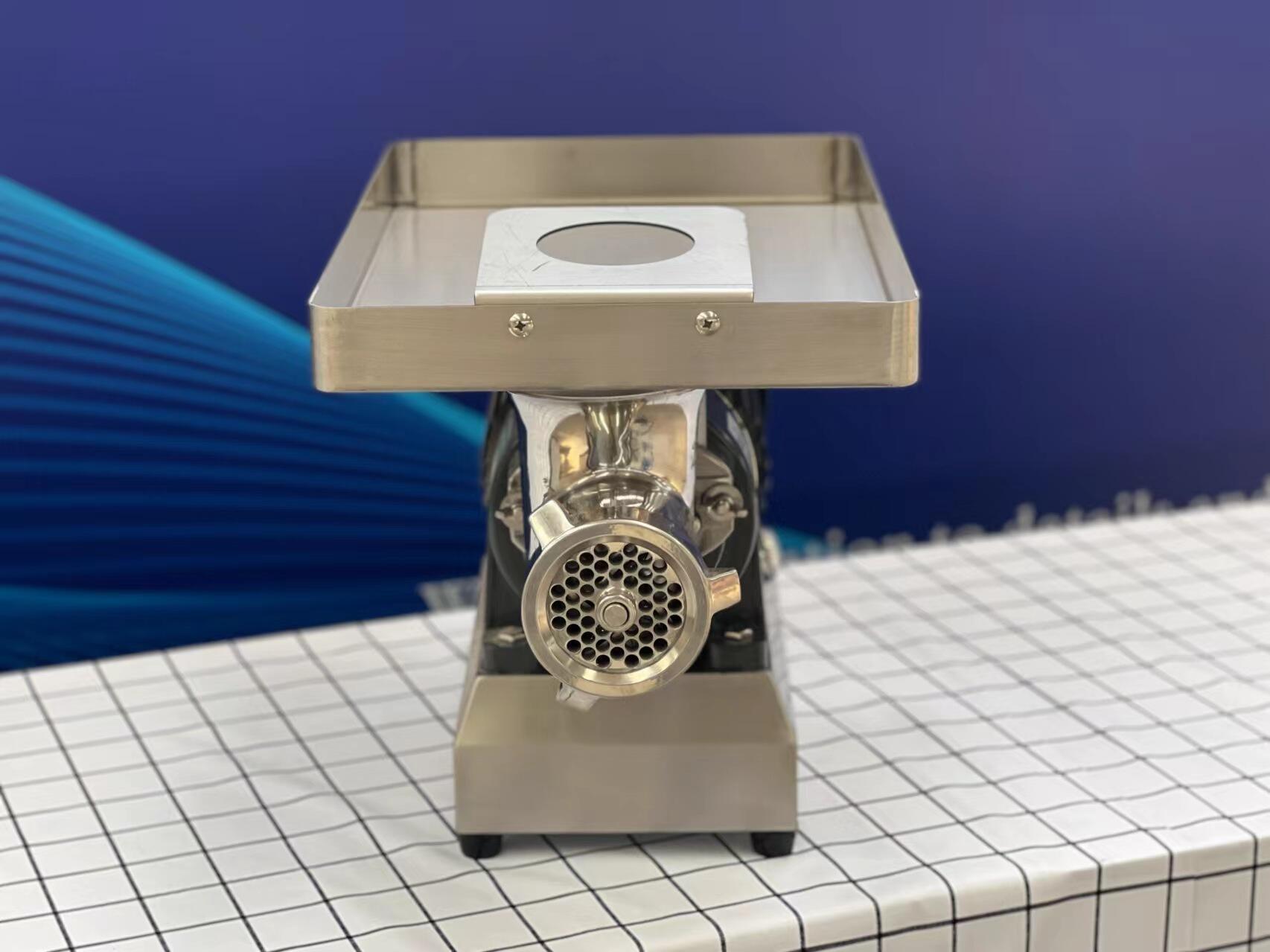

noodles production machine

The noodles production machine represents a state-of-the-art solution for automated noodle manufacturing, combining precision engineering with efficient production capabilities. This advanced equipment handles the complete noodle-making process, from mixing raw ingredients to the final cutting stage. The machine features a high-capacity mixing system that ensures uniform dough consistency, coupled with an advanced extrusion mechanism that maintains proper texture and density. Its sophisticated temperature control system monitors and adjusts heat levels throughout the production process, guaranteeing consistent product quality. The cutting mechanism offers versatile options for various noodle styles and thicknesses, while the integrated moisture control system ensures optimal dough hydration. With production capacities ranging from 100 to 500 kg per hour, the machine accommodates both small-scale operations and industrial-level production requirements. The automated control panel provides user-friendly operation with precise parameter adjustment capabilities, while the stainless steel construction ensures durability and meets food safety standards. This machinery is designed to produce various noodle types, including instant noodles, fresh noodles, and dried noodles, making it a versatile solution for diverse market demands.