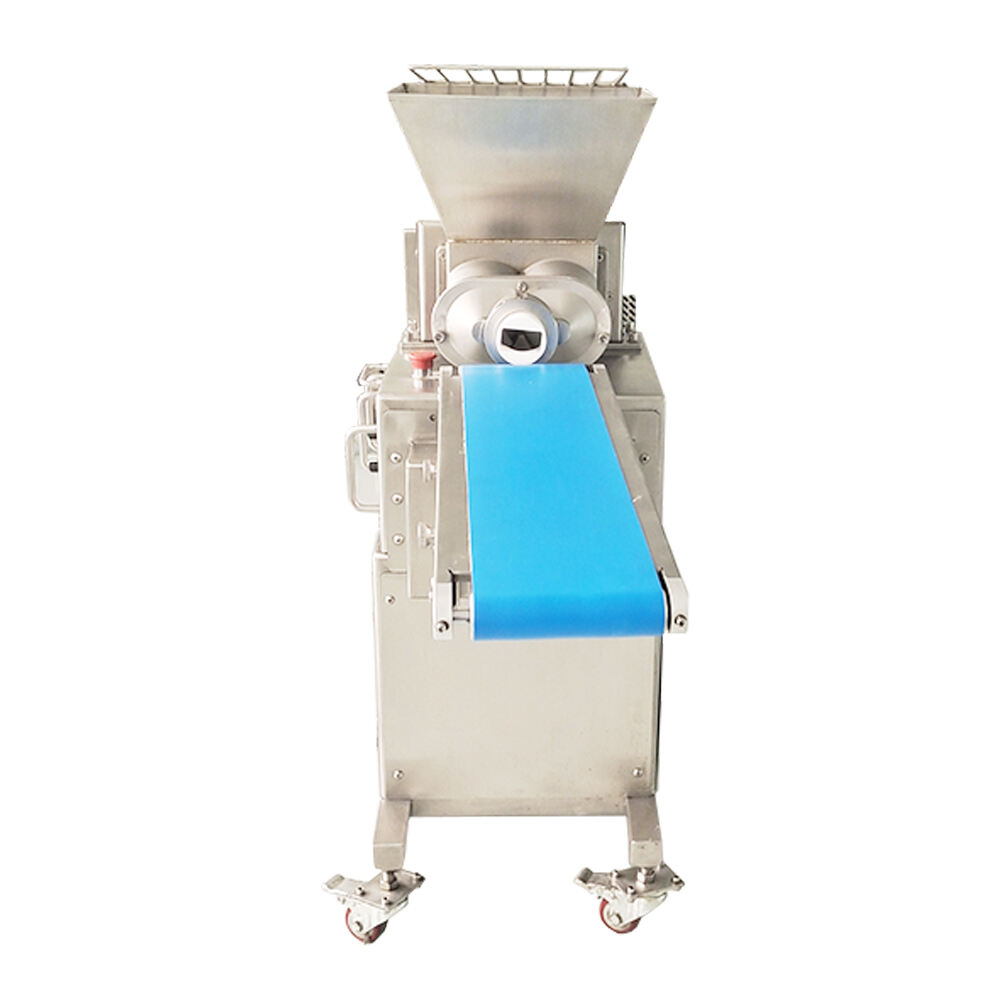

chocolate making machine

A chocolate making machine represents a sophisticated piece of equipment designed to transform raw cocoa ingredients into refined chocolate products. This advanced system incorporates multiple stages of processing, including mixing, refining, conching, and tempering, all within a single integrated unit. The machine features precision temperature control systems that maintain optimal conditions throughout the production process, ensuring consistent quality in the final product. Digital controls allow operators to adjust parameters such as mixing speed, temperature, and processing time with exceptional accuracy. The machine's automated functions handle everything from initial mixing of ingredients to the final tempering process, which gives chocolate its characteristic shine and snap. Modern chocolate making machines are equipped with stainless steel components that ensure hygiene and durability, while their efficient design minimizes waste and maximizes production output. These machines can process various types of chocolate, including dark, milk, and white varieties, with the capability to handle different batch sizes depending on production needs. The technology incorporated includes precise heating elements, powerful mixing motors, and sophisticated cooling systems that work in harmony to create professional-grade chocolate products.