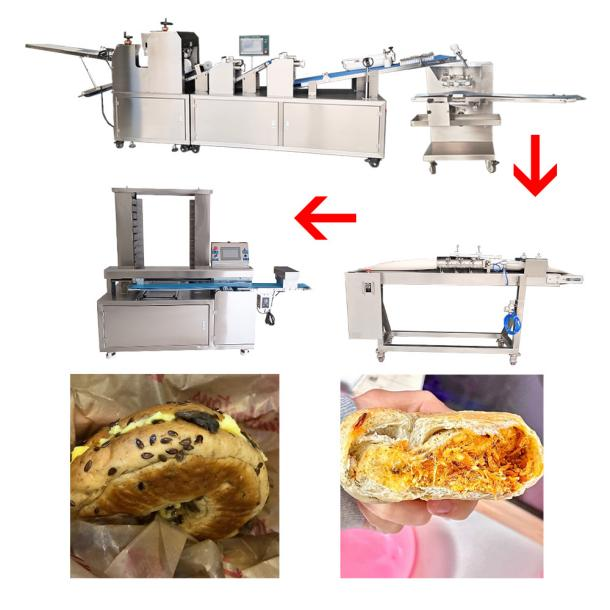

industrial bread production line

The industrial bread production line represents a comprehensive baking solution that revolutionizes commercial bread manufacturing. This advanced system integrates multiple stages of bread making into a seamless, automated process, starting from ingredient mixing through to final packaging. The line typically consists of several key components: an automated dough mixing system, a primary fermentation chamber, a dough dividing and rounding unit, intermediate proofing equipment, a final molding station, secondary fermentation controls, and a precision baking system. Each component is carefully calibrated to ensure consistent quality and optimal production efficiency. The line can handle various bread types, from standard loaves to artisanal varieties, with production capacities ranging from 500 to 4,000 pieces per hour, depending on the configuration. Advanced control systems monitor critical parameters such as temperature, humidity, and timing throughout the process, ensuring precise consistency in the final product. The integration of modern IoT technology allows for real-time process monitoring and adjustment, while smart sensors maintain quality control standards. This production line significantly reduces manual labor requirements while maintaining high hygiene standards through its stainless steel construction and automated cleaning systems. The modular design enables customization based on specific production needs and available space, making it suitable for both medium-sized bakeries and large-scale industrial operations.