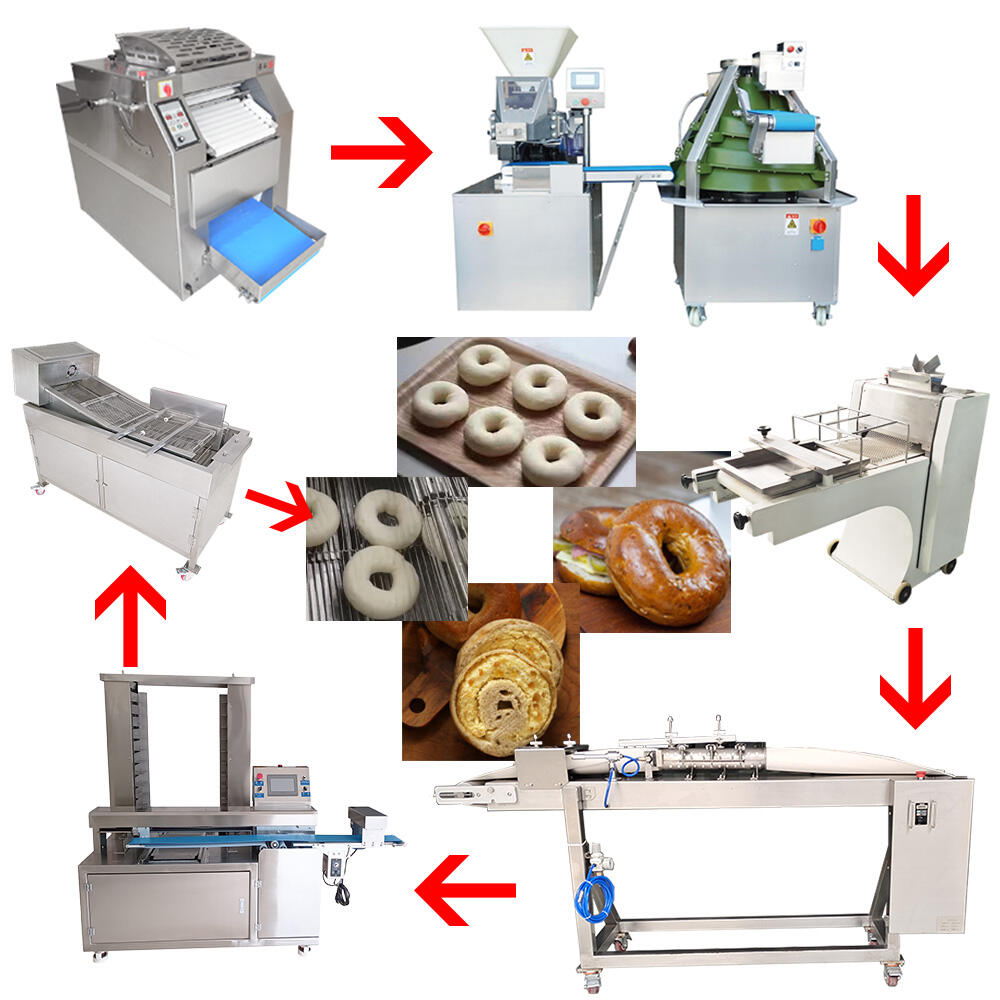

industrial croissant machine

An industrial croissant machine represents a significant advancement in commercial bakery automation, designed to produce consistent, high-quality croissants at scale. These sophisticated machines integrate multiple processes, from dough sheeting to precise layering of butter and final shaping. The equipment features programmable controls that manage dough temperature, thickness, and folding patterns, ensuring each croissant meets exact specifications. Modern industrial croissant machines can produce thousands of units per hour while maintaining the delicate laminated structure that defines premium croissants. The system typically includes a series of rollers for dough sheeting, automated butter sheeting mechanisms, and cutting stations that create the signature triangular shapes. Advanced models incorporate precision temperature control systems to maintain optimal conditions throughout the production process, particularly crucial for preserving butter consistency. The machines also feature adjustable speed settings, allowing bakers to fine-tune production rates according to their needs. Safety features include emergency stop buttons, protective guards, and automated cleaning systems that ensure both operator safety and product hygiene. These machines can accommodate various dough types and recipes, making them versatile additions to any commercial bakery operation.