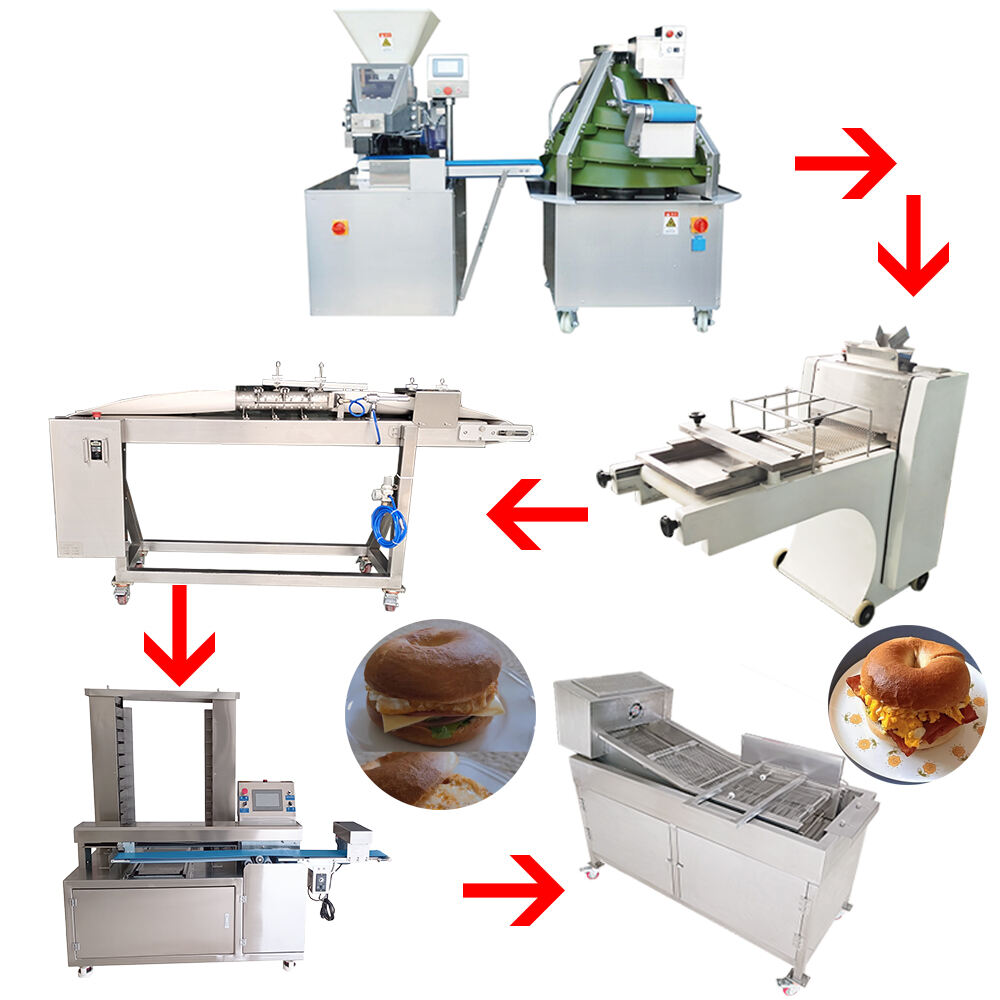

customized bakery production line

A customized bakery production line represents a comprehensive solution that transforms raw ingredients into finished baked goods through a series of automated processes. These advanced systems integrate multiple components including mixing stations, dough processing units, proofing chambers, and baking ovens, all tailored to meet specific production requirements. The line's technological features include precision temperature control systems, automated ingredient dispensing mechanisms, and programmable logic controllers that ensure consistent product quality. The equipment can be configured to handle various dough types and produce different bakery items, from bread and rolls to pastries and cookies. Modern customized bakery lines incorporate smart monitoring systems that track production parameters in real-time, allowing for immediate adjustments to maintain optimal performance. These lines are designed with modular components, enabling easy maintenance and future upgrades. The application scope extends from artisanal bakeries seeking to scale up production to large industrial facilities requiring high-volume output. Each component is engineered to work in harmony, maximizing efficiency while maintaining product quality and consistency.