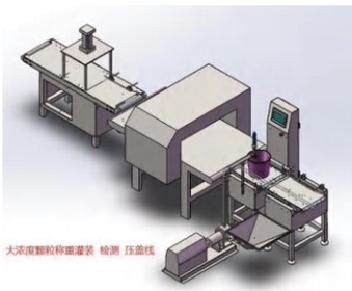

mousse filling line

A mousse filling line represents a sophisticated automated system designed specifically for the efficient production and packaging of mousse-based products. This advanced production line integrates multiple processes, including mixing, aerating, filling, and packaging, all within a single streamlined system. The line's primary functions encompass precise ingredient dosing, consistent texture development, and accurate filling operations, ensuring product uniformity across every batch. The system utilizes state-of-the-art technology to maintain optimal temperature control throughout the production process, preserving the delicate structure of mousse products. The line's versatility allows for the processing of various mousse formulations, from classic chocolate and fruit varieties to innovative flavor combinations. Advanced servo-driven filling mechanisms ensure precise portion control, while integrated cleaning systems maintain strict hygiene standards. The line's modular design facilitates easy maintenance and potential expansion, making it adaptable to growing production needs. Temperature-controlled hoppers and pipes prevent product degradation, while automated quality control systems monitor consistency and filling accuracy. The technology particularly excels in maintaining the characteristic light, airy texture of mousse products throughout the production cycle, ensuring end products meet both quality and aesthetic standards.