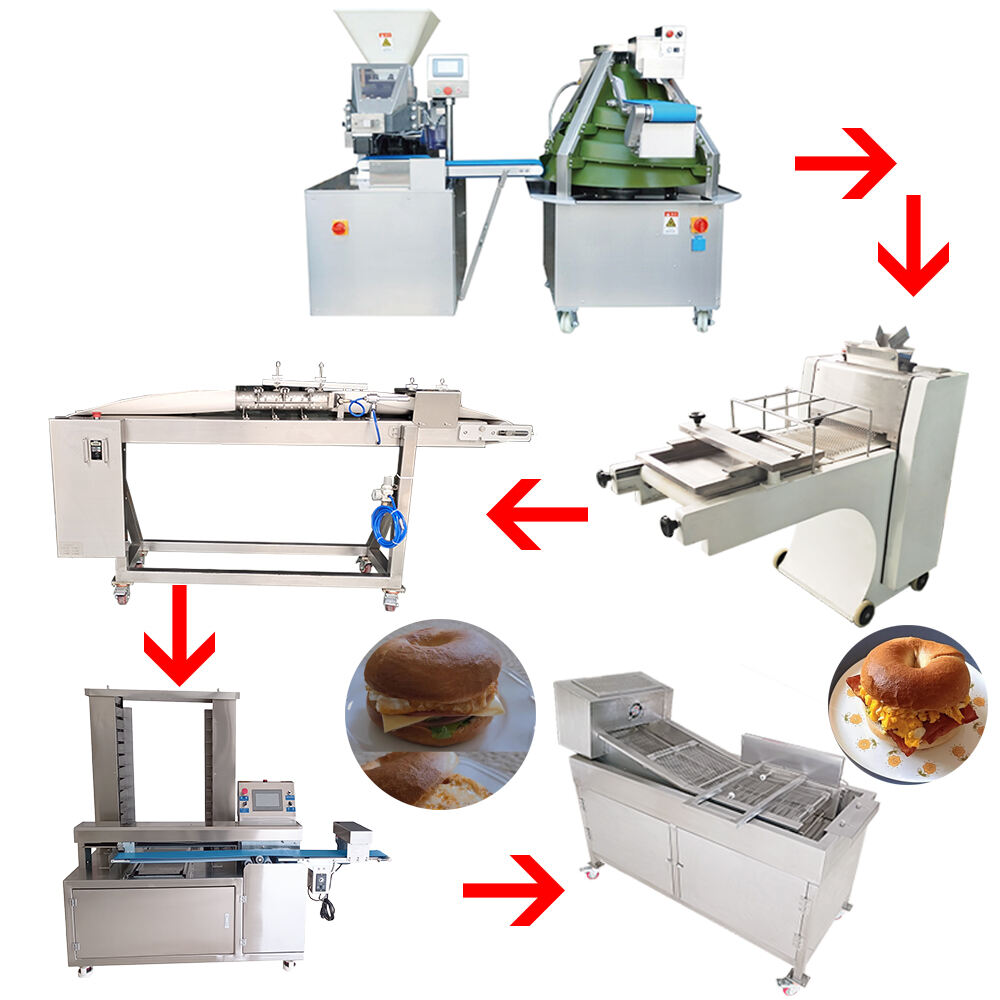

puff pastry production line

A puff pastry production line represents a sophisticated automated system designed to streamline the creation of delicate, multi-layered pastries at a commercial scale. This advanced machinery combines precision engineering with traditional baking principles to produce consistently high-quality puff pastry products. The line typically consists of several integrated stations, including dough mixing, laminating, folding, and cutting components. The process begins with the automated mixing of ingredients, where flour, water, and fat are combined to create the base dough. The distinguishing feature of this production line is its laminating system, which creates the characteristic layers by repeatedly folding and rolling the dough with butter or margarine. Advanced temperature control systems maintain optimal conditions throughout the process, ensuring the butter remains at the perfect consistency for lamination. The cutting station employs precision blades to shape the pastry into desired formats, while conveyor systems smoothly transport products between stations. Modern puff pastry lines often incorporate smart controls and monitoring systems that allow operators to adjust parameters in real-time, ensuring consistent quality across batches. These production lines can handle various product specifications, from croissants to vol-au-vents, making them versatile additions to any commercial bakery operation.