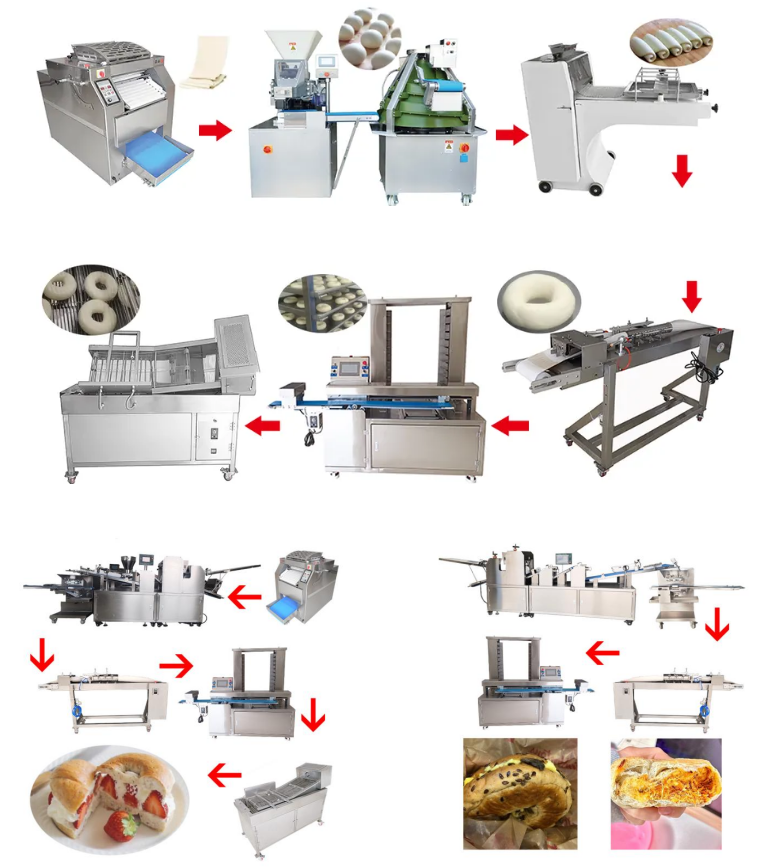

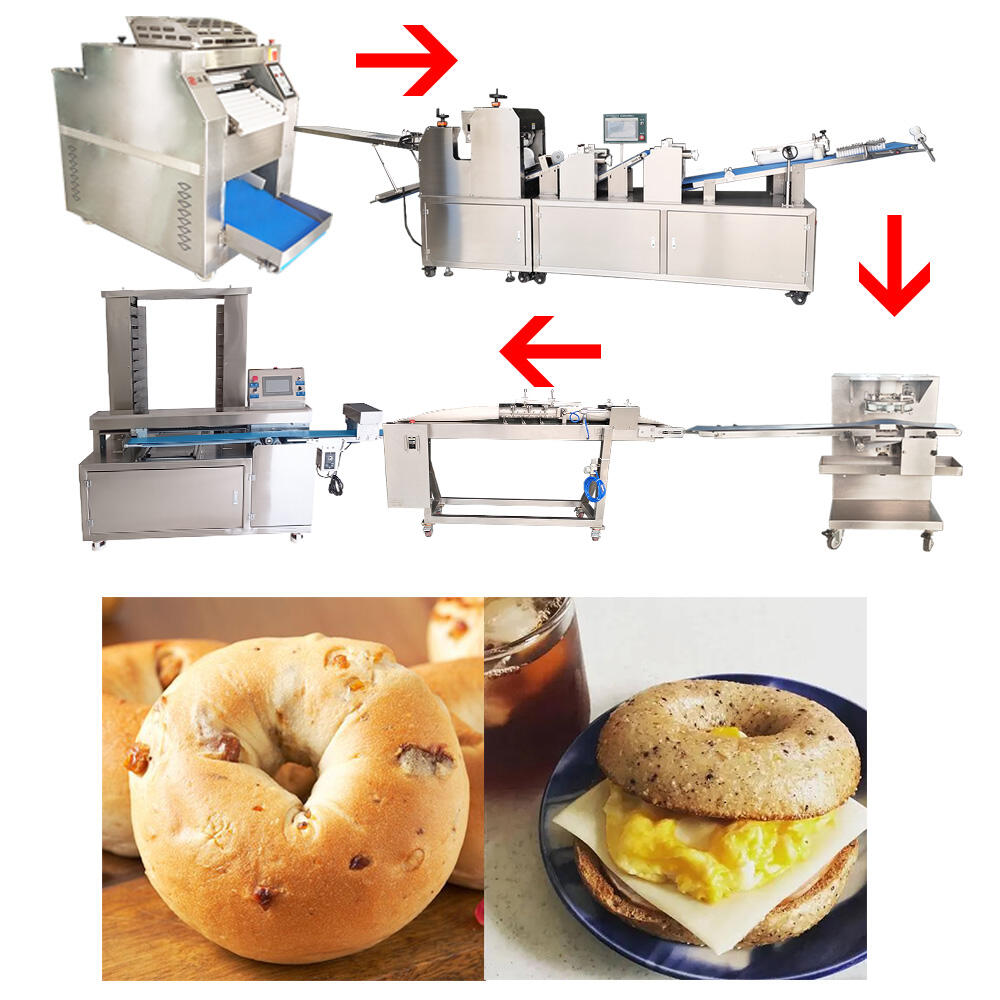

doughnuts maker machine

A doughnuts maker machine is a specialized kitchen appliance designed to streamline the process of creating perfect doughnuts consistently. This innovative device features a non-stick cooking surface with specially shaped molds that ensure uniform size and shape for each doughnut. The machine typically operates with advanced heating elements that provide even heat distribution, resulting in perfectly cooked doughnuts every time. Modern doughnut makers come equipped with temperature control systems, allowing users to adjust the heat settings for different recipes and batters. The cooking plates are engineered to create the characteristic doughnut shape while maintaining optimal heat circulation for even browning. Most models can produce multiple doughnuts simultaneously, significantly increasing production efficiency compared to traditional frying methods. These machines often include safety features such as cool-touch handles, non-slip feet, and automatic shut-off functions. The compact design makes it suitable for both commercial and home use, while the sealed cooking system prevents oil splatter and reduces mess. Many models also feature indicator lights that signal when the unit is ready for use and when the doughnuts are fully cooked.