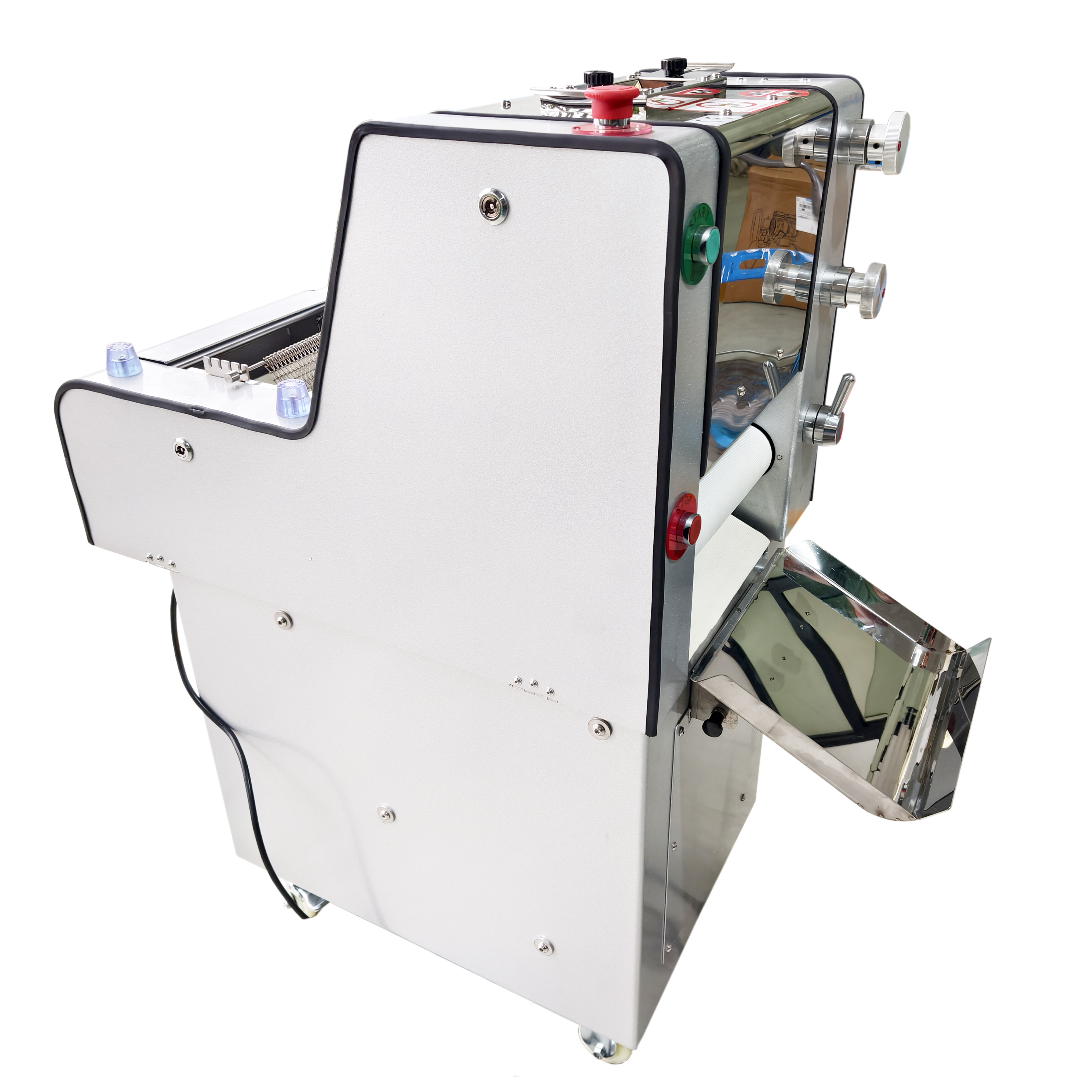

commercial pastry roller

A commercial pastry roller represents a vital piece of equipment in professional bakeries and food service establishments, designed to streamline the dough processing workflow. This sophisticated machine combines precision engineering with user-friendly operation to achieve consistent dough thickness and texture across various pastry applications. The roller features adjustable height settings, allowing bakers to achieve exact specifications for different pastry types, from delicate croissants to sturdy pie crusts. Built with food-grade stainless steel components, these machines ensure both durability and hygiene in commercial kitchen environments. The automated rolling mechanism significantly reduces physical strain on workers while maintaining uniform dough quality. Modern models incorporate advanced features such as variable speed controls, safety guards, and easy-clean surfaces. The roller's design typically accommodates different dough volumes, making it suitable for both small artisanal bakeries and large-scale production facilities. Additionally, these machines often feature precise thickness gauges, enabling bakers to maintain product consistency across batches.