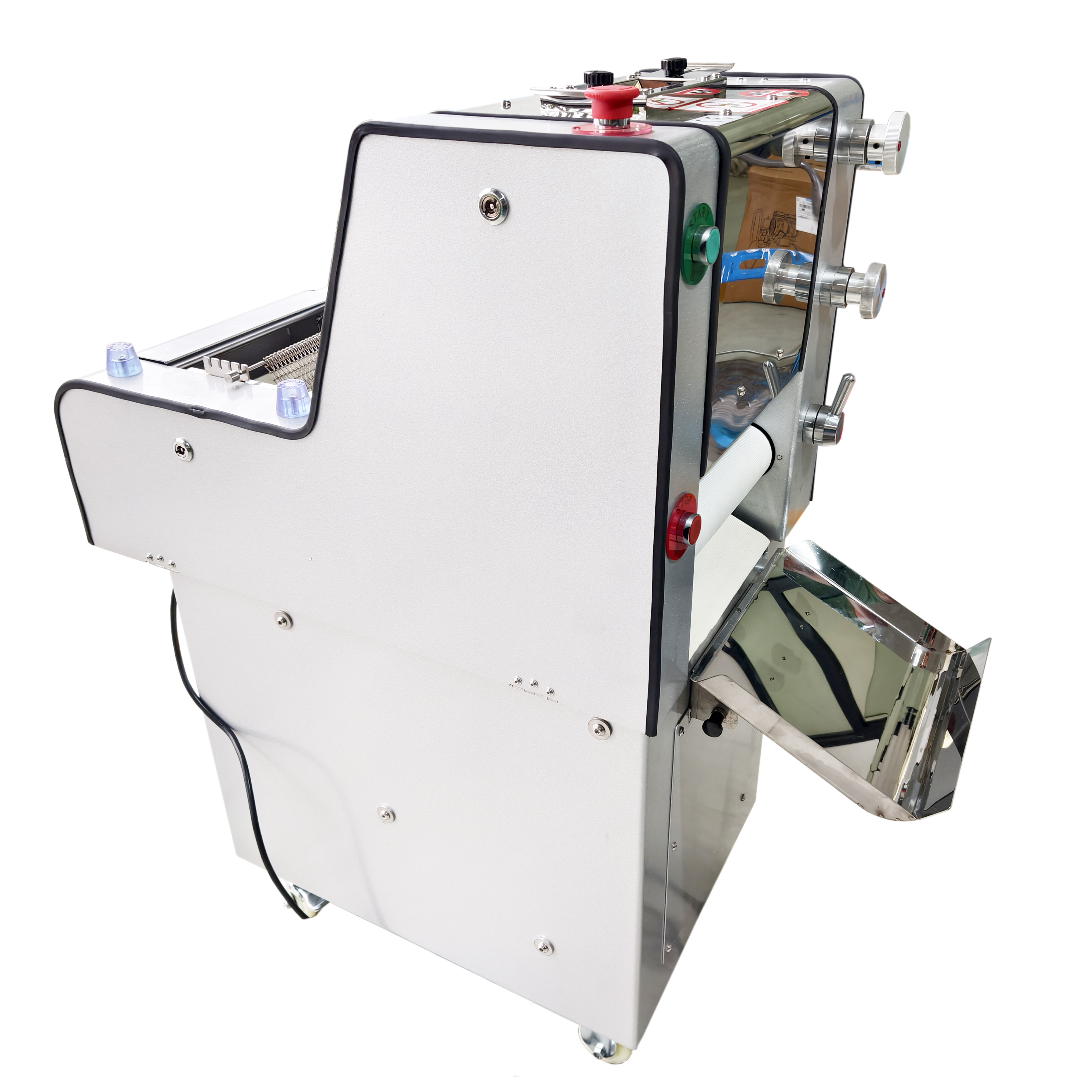

commercial bread baking machine

The commercial bread baking machine represents a cornerstone of modern bakery operations, combining precision engineering with advanced baking technology. This sophisticated equipment streamlines the bread-making process through automated mixing, kneading, proofing, and baking functions, all integrated into a single efficient unit. The machine features digitally controlled temperature and humidity settings, ensuring consistent results across multiple batches. With customizable programs for different bread varieties, it can handle various dough types and recipes, from traditional white bread to artisanal specialties. The system incorporates multiple safety features, including emergency shut-off mechanisms and temperature alerts. Its stainless steel construction ensures durability and easy cleaning, while the enhanced insulation system optimizes energy efficiency. Modern models come equipped with touch-screen interfaces, allowing precise control over baking parameters and cycle times. The capacity ranges from 50 to 200 loaves per hour, depending on the model, making it suitable for both medium-sized bakeries and large-scale operations. Advanced models feature integrated diagnostic systems that monitor performance and alert operators to potential maintenance needs, ensuring minimal downtime and optimal operation.