commercial baking equipment

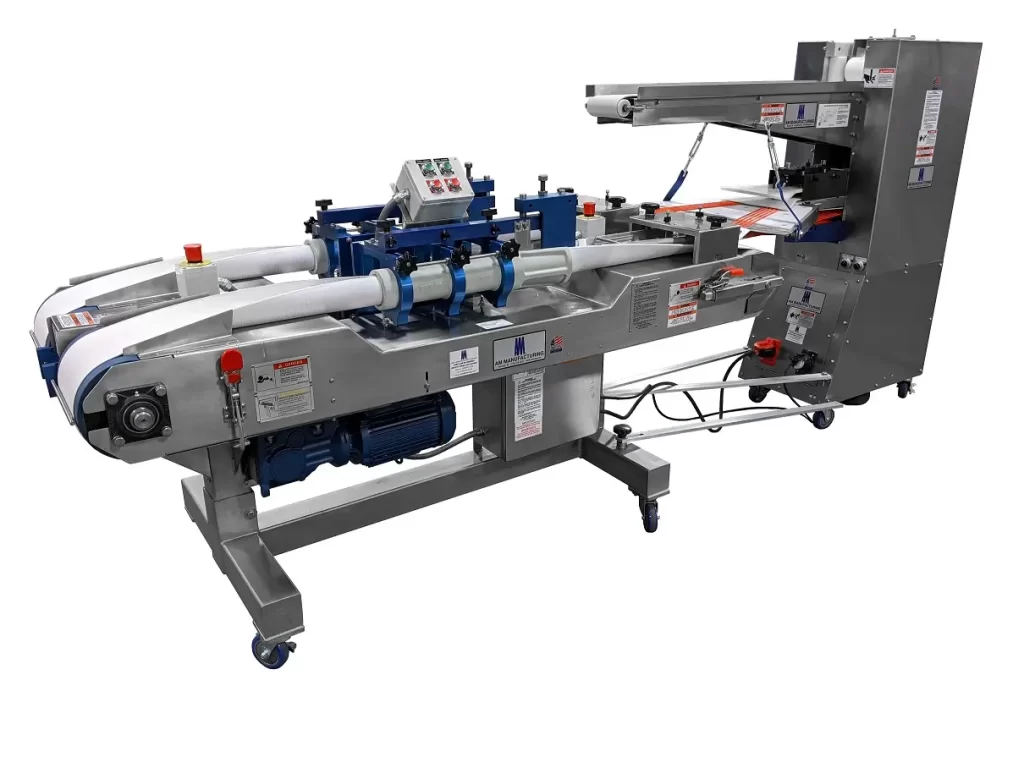

Commercial baking equipment represents the backbone of modern bakery operations, encompassing a comprehensive range of specialized machinery designed to streamline and enhance the baking process. These sophisticated systems include industrial ovens, mixers, dough sheeters, proofing cabinets, and automated packaging solutions. Modern commercial baking equipment features advanced temperature control systems, precise humidity regulation, and programmable settings that ensure consistent results across large-scale production runs. The equipment is engineered with food-grade stainless steel construction, incorporating innovative technologies such as digital controls, energy-efficient heating elements, and automated cleaning systems. These machines are capable of handling high-volume production while maintaining product quality and uniformity. The versatility of commercial baking equipment allows for the production of various baked goods, from artisanal bread to pastries and cakes, with customizable settings for different recipes and baking requirements. Safety features include emergency shut-off systems, temperature alerts, and ergonomic designs that protect operators while maximizing productivity. The integration of smart technology enables real-time monitoring, production tracking, and preventive maintenance scheduling, ensuring optimal performance and reduced downtime.