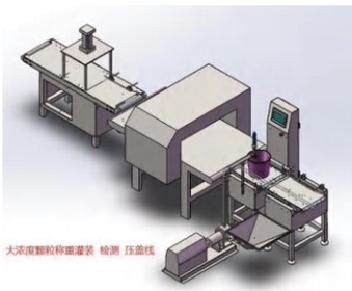

automated bakery production line

The automated bakery production line represents a cutting-edge solution for modern industrial baking operations, integrating multiple processing stages into a seamless, efficient system. This comprehensive setup typically includes modules for ingredient handling, mixing, dough processing, proofing, baking, cooling, and packaging. The line utilizes advanced PLC control systems that ensure precise temperature regulation, timing coordination, and quality consistency throughout the production process. Smart sensors monitor various parameters such as humidity, temperature, and dough consistency, making real-time adjustments to maintain optimal conditions. The production line can handle various product types, from bread and rolls to pastries and cookies, with quick changeover capabilities between different recipes. Material handling systems, including conveyor belts and automated transfer mechanisms, minimize manual intervention and ensure continuous production flow. The system's modular design allows for easy maintenance and future expansion, while integrated cleaning systems maintain hygiene standards. Modern automated bakery lines can achieve production rates of up to several thousand units per hour, making them ideal for medium to large-scale operations.