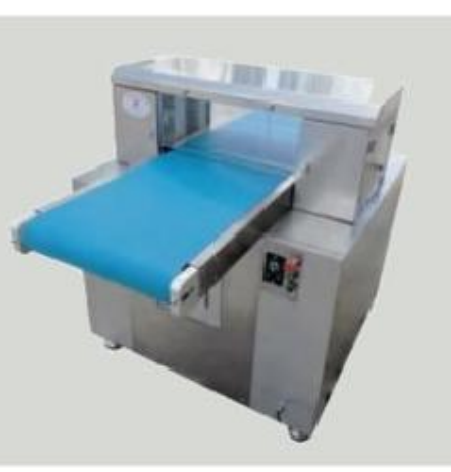

professional baking tools

Professional baking tools represent the cornerstone of successful baking operations, combining precision engineering with practical functionality to deliver superior results. These essential implements include high-grade mixing bowls, precision scales, temperature-controlled proofing cabinets, commercial-grade ovens, and specialized utensils designed for various baking techniques. Digital temperature probes ensure precise monitoring of both ingredient and ambient temperatures, while calibrated measuring tools guarantee consistency in recipe execution. Modern professional baking tools often incorporate advanced features such as digital controls, programmable settings, and ergonomic designs that enhance efficiency and reduce physical strain. The tools are crafted from durable materials like stainless steel, food-grade silicone, and heat-resistant plastics, ensuring longevity and maintaining food safety standards. These implements are designed to handle the rigorous demands of commercial baking, supporting high-volume production while maintaining consistent quality. The integration of smart technology in many modern baking tools allows for precise control over variables such as temperature, humidity, and timing, resulting in more predictable and reliable outcomes.