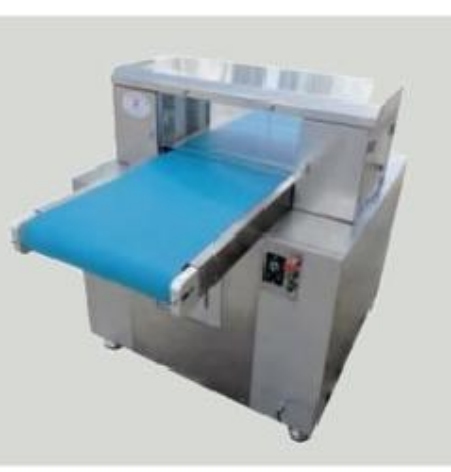

cake cream spreading machine

The cake cream spreading machine represents a revolutionary advancement in bakery automation, designed to deliver precise and uniform cream application across various baked goods. This sophisticated equipment streamlines the traditionally manual process of cream spreading, offering consistent results while significantly reducing production time and labor costs. The machine features an adjustable spreading mechanism that can handle different cream consistencies and accommodate various cake sizes, making it versatile for diverse bakery operations. Its state-of-the-art design incorporates a user-friendly control panel that allows operators to customize spreading parameters, including thickness, speed, and pattern distribution. The machine's stainless steel construction ensures durability and meets strict hygiene standards, while its efficient spreading system minimizes waste and maintains product quality. Advanced features include temperature control systems to maintain optimal cream consistency, automated cleaning cycles for enhanced sanitation, and quick-change attachments for different spreading patterns. The technology encompasses precision nozzles that guarantee even distribution and can be adjusted for different decorative patterns, making it suitable for both industrial-scale bakeries and specialty cake shops.