pretium machinae faciendarum panem commercialiter

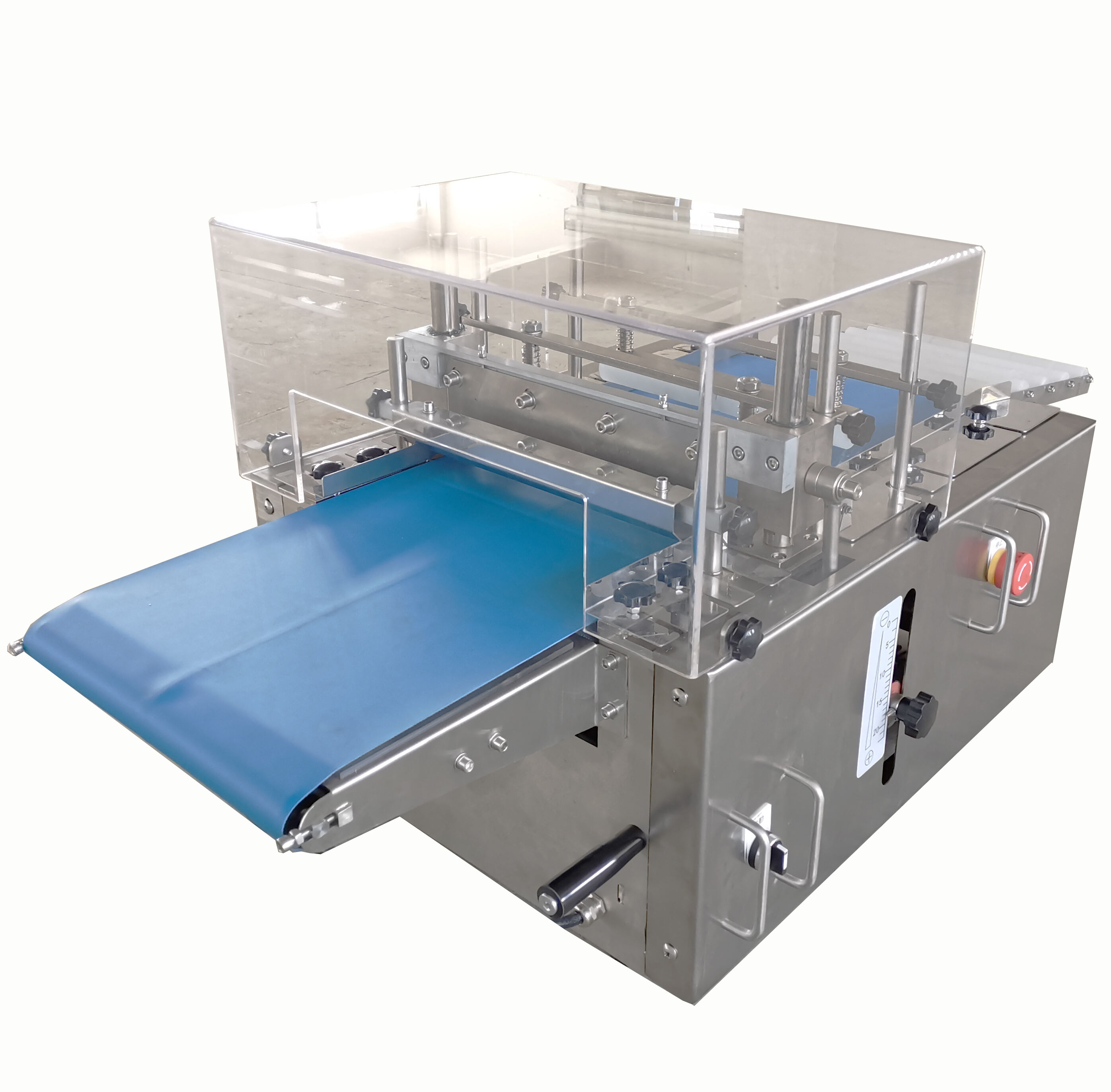

Praecia machinarum panificiarum commercialium varie fluctuant secundum capacitem, characteristicas et famam brand, commode ab $1,500 usque ad $15,000 extendentes. Haec instrumenta investmenta essentialia pro pistoriis, coenobiis et institutionibus servitiorum cibariis praebent, solutiones automatizatas pro constanti productione panis altissimae qualitatis offerendo. Machinae commercialis recentis aevi characteristicas avances tales ut recettas programmabiles, plures velocitates amassandi et systema praecise controllandi temperaturam includunt. Eae varios generes conspersiones et recettas tractare possunt, ab pane albo basico usque ad species artesanales, cum capacitatibus productionis ab 20 usque ad 200 panes per fasciculum. Haec machinae saepe feature constructionem ex aere inoxydabili, panelia digitalia controllo et operationes efficientes energetice. Eae characteristicas securitatis tale ut buttons emergentis stop, protectionis overload et systemata automati shutdown includunt. Punctum praeciae saepe additionalia capacitatem reflectit tale ut functiones proofing, plures paddles mixtiones et systemata ingredientium dispensandi automate. Considerationes investmenti debent accountum capere requisitiones voluminis productionis, spatium disponibile, et necessitates specificas varietatum panis.