machina et apparatus panificatorii

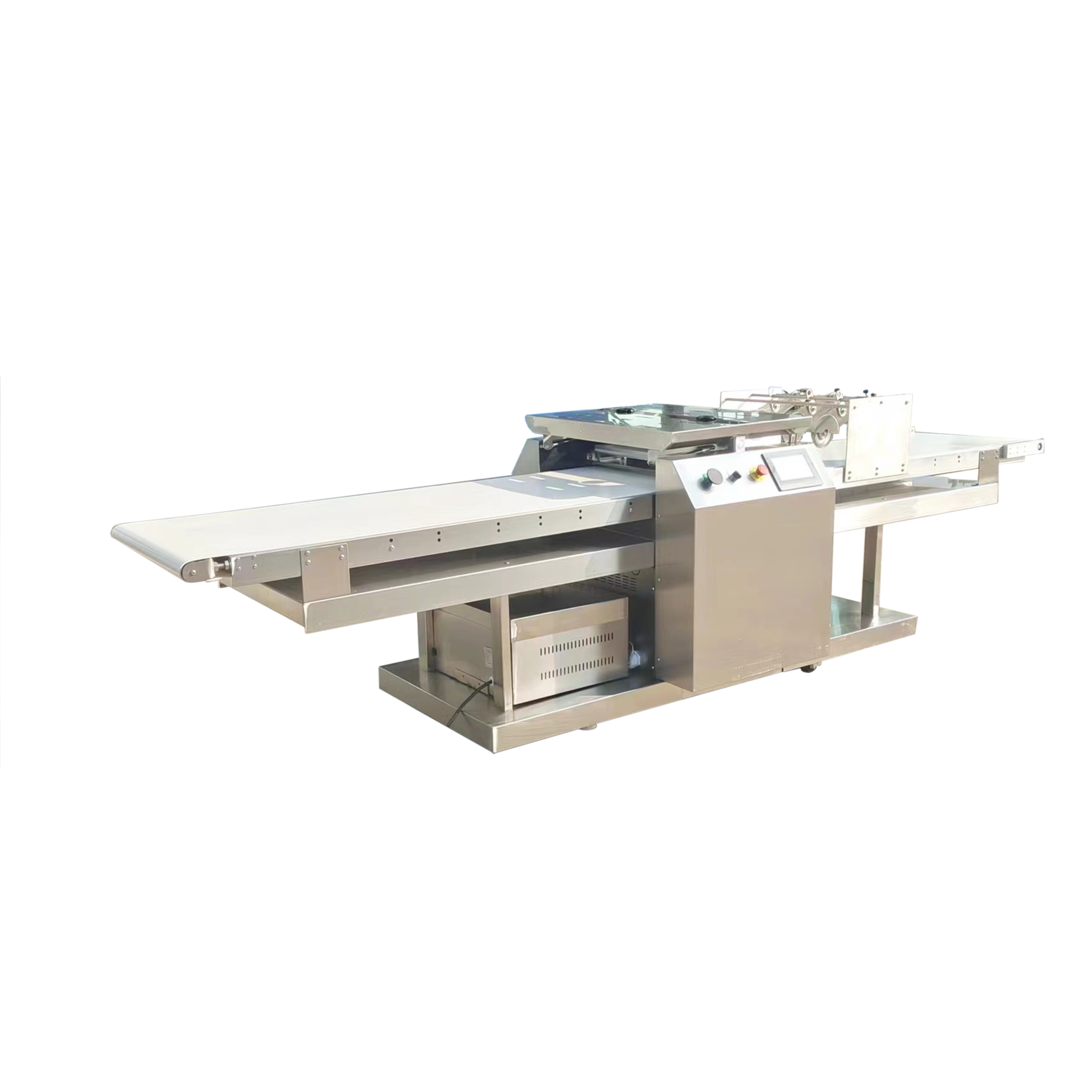

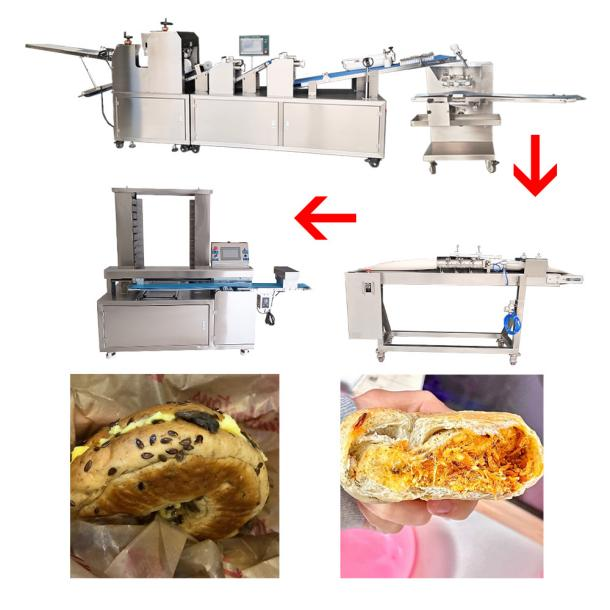

Machinamenta et instrumenta panificatorii sunt fundamentum operationum commercialium panis huius temporis, comprehendentes vaste spectrum operum specialium et systematum automatizatorum ad processum panificandi optimizandum. Haec necessaria machina comprehendent systemata permiscendi quae constantiam praeparationis consulis assequuntur, dividentes praecise consules uniformitatem producti conservantes, et camaras elaboratas pro fermentando quae condiciones optime pro evolvendo consulis creant. Forni periti cum multis zonis coctionis et systematibus praecise controlis caloris perfectos effectus coctionis semper pollicentur. Machina incorporat technologiam ultimam sicut panellos controlis digitalis, conservationem programmabilium reciperiorum, et systemata curarum automatizatarum, operationes efficacius et fidelius reddens. Instrumenta panificatorii moderni etiam opera specialia ad conficiendum cibaria dulcia, sectandum panem, et solutiones ambulatorii quae vitam producti in mensura longiore extendunt includunt. Integratio harum machinarum lineam productionis continuam creat quae magna volumina ordinum tractare potest dum qualitatem producti servat. Feature curarum sicut systemata clausurae urgentis et materiales resistentes calori operatoris tutelam conservant, dum designa economica energiae operationales costus minuunt. Haec machinae constructae sunt ut normas severas hygienicarum expleant, cum constructione ferri nucleani et superficies facile lavabiles quae regulas sanitatis alimentorum complent.