The Flexibility of Modern Bakery Production Lines

Adapting to Market Demands

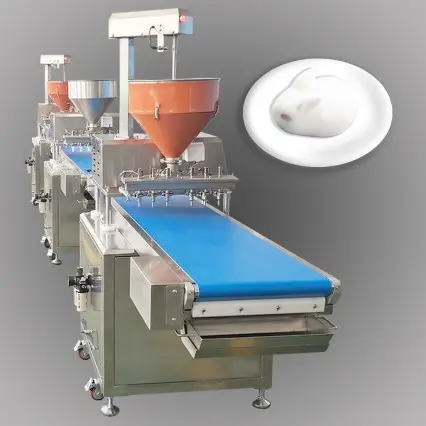

Today all sorts of bakery production lines offer increasing flexiblity, enabling bakeries to adjust quickly to shifts in consumer tastes driven by fads, diets and the weather. This agility is essential because consumer needs can shift quickly, requiring a rapid shift in production. Real-time adjustments in volume are possible with the implementation of smart manufacturing technology (SMT) in such production lines. This means that bakeries can react to lots in small batches or large volume orders. There is evidence that production of bakeries being able to operate in a more flexible way have a higher customer satisfaction and lower waste level because these bakeries do not overproduce and buy and make goods that are demand sensitive.

Customization Capabilities

The robots of today's bakery have put the power of customization in the hands of customers, allowing bakery patrons to easily create their own custom mixes and taste sensations. Modular equipment allows bakeries to pivot recipes or ingredients with little to no downtime, and that bodes really well for the consumer experience. It is not only meets people’s individual preference, but also saves labor time in production. Hand in hand with this trend, a recent report by a prominent bakery industry association demonstrates a significant sales growth trajectory for bakeries selling personalized baked goods, further evidencing the business opportunities in adopting personalization in bakery production.

Essential Bread Varieties Produced at Scale

Artisan-Style Loaves and Sandwich Bread

Today, both small independents and large industrial bakeries can meet the demand for artisan-style loaves without a sacrifice to quality. The large volume production lines permit these bakers to keep their 'artisan' image. By adding old methods like long fermentation into automated systems, bakeries offer unique flavor profiles. Market research indicates a growing consumer demand for products that include premium ingredients, that convey taste as well as nutritional value in the final product. This is further evidence of the artisan breads market responding to consumer appeal, and producers' ability to meet volume demands.

Crusty Baguettes and Dinner Rolls

The firm is using ultra-modern technology for the production of baguettes, that includes steam-injection methods to create the same environment as a traditional baking oven. This technique is what allows us to obtain the type of crust we want to see in a classic baguette. In the same way, dinner rolls are mass-produced rapidly and uniformly with state of-the art equipment that ensures consistency of size and texture. These are also essential steps for meeting high-volume catering needs. Studies have shown that appropriate baking techniques can increase yields and quality and as such these are some of the bread products baked in large capacity bakery lines.

Soft Hamburger Buns and Hot Dog Rolls

This is what "softie" hamburger buns or hot dog rolls require, managing the ingredient proportions, and baking protocol, to produce a delicate-yet-strong foodstuff. These buns are specifically designed to carry the most toppings, a premium quality necessary both for millennial food-and-drink sensibilities (fast-casual dining) and outdoor barbecue and festival atmospheres. Novel baking methods for their production result in storage stability, plus products stay fresh for prolonged period. Recent sales figures down are showing that there has been a serious rise in the need for these soft buns, thanks to the increased hunger for barbecues and fast casual dining experiences, reinforcing the need for an effective hamburger bun production in bulk.

Pastry Production: From Croissants to Danishes

Laminated Doughs for Flaky Croissants

The production of flaky croissants is predominated by use of dough laminating, mostly using technology such as automated systems. These systems guarantee uniform layering - one of the key factors for obtaining the typical flakiness of real croissants. Advances in temperature control are important to the integrity of the dough during production, for in precise conditions of temperature, the dough does not break down as it is formed. These studies also demonstrate that uniformity in lamination means less waste material, better consistency in the end product and increased customer satisfaction. This approach also resonates well with the increasing consumer appetite for that artisanal quality even in something as mass-produced as gumballs.

Fruit-Filled Danish Pastries

Today's pastry lines are able to incorporate fruit fillings directly into day-old pastries - to both extend flavor and improve eye-appeal. With these methods, such as automatic filling stations, bakers can do all of this and still keep their operation running. Market investigations have also shown a strong desire from consumers to select a product which carries a natural fruit filling, offering them a healthier proposition when it comes to Danish pastries. This demand for natural ingredients by consumers pushes bakeries to keep reinventing themselves and offer attractive and healthy options to their consumers.

Puff Pastry Applications in Savory Snacks

High capacity puff production lines are designed with precision to cater both sweet and savoury products due to the versatility of the puff pastry. The special properties of puff pastry need extreme dough handling that might expertly and repeatedly be done by high-speed machines. There are reports of a greater acceptance for savory snacks, which is driving the bakery innovation in puff pastry usages. This movement is driving bakeries to develop new savory recipes that leave consumers with an array of taste sensations, inspired by creative and flavorful savory goods. This agility enables them to broaden their product ranges and minimise time to market.

Cakes and Muffins: Automated Sweet Treats

High-Volume Sheet Cake Production

Large-volume sheet cake product lines are so well-dialed to require the uniform dimensions and fast bake times needed by high volume manufacturing. These automatic systems rely on consistent quality through use of accurate timing and temperature control. In addition, incorporation of automated frosting and decorating operations adds beauty to the cake as well as speed and efficiency to provide fast production turns. Market knowledge suggests that the appetite for sheet cakes (particularly in event catering segments) is strong for a product that is ready and easy to serve. This request exemplifies the need for efficiency in the process of making sheet cakes.

Uniform Cupcake Manufacturing

The manufacturing lines of cupcakes are delicately designed to guarantee even baking and weight control, which both play important roles in the consistency of products. With advances in decorating technology, cupcakes can be decorated quickly, leading to higher turnover production rates. This trend runs at a fast pace and complements a consumer trend for sophisticated cupcake products so this only goes to support the need for decorative skills. Manufacturers can meet consumer expectations and stay competitive in the market for good-looking and good-tasting cupcakes that their customers are demanding with attractive, uniform cupcakes made with Babcock ingredients.

Specialty Muffin Variations

In the specialty muffin market, automated machinery flexibly addresses varying dietary trends – such as gluten-free and vegan variants – to deliver the popular trend of consumers looking for healthier snacking alternatives. Yet the focus on quality means that bakers can develop distinct flavour profiles for their products that make it difficult for their goods to be challenged in an increasingly crowded space. Studies show a strong trend towards healthier snacking choices among consumers, which bodes well for these wide range muffins. Manufacturers that learn and understand these trends will ride the wave of changing consumer taste trends and stay competitive in the category of specialty muffins.

Cookies and Biscuits: Precision Mass Production

Consistent-Shaped Cookies for Packaging

It’s critical that cookies all have the same shape and size (not just for packaging but also for branding). Precision technology is key to maintaining this consistency, the same batch after batch. More Efficient Batch sizes are a critical element, and by the right-sizing them, bakeries can dramatically improve their efficiency and production costs. With consumer demands continuing to increase, the pursuit of quality and consistency in products, raises the popularity of high-precision mass production in the cookie industry.

Sandwich Biscuit Assembly Lines

Special assembly lines for sandwich biscuits make fast and efficient production possible and thousands of products every minute can be produced. Automation filling dispensers are included in all units to guarantee accurate feeding of filling and thus very high product quality is achieved. Present sales figures point toward a vibrant market for sandwich biscuits, especially for new flavours and fillings and having automated assembly lines is one of them.

Decorated Cookies with Automated Toppings

Utilizing automation for cookie decorating allows bakers to produce complex designs which improve the attractiveness of the products without increasing labor costs. And advances in technology allow bakeries to create cookies that are seasonal or themed and which will appeal to an array of ages and interests. Decorated cookies are an emerging category according to market research with personalisation and decoration trends becoming popular in the baking category.

FAQ Section

What makes modern bakery production lines flexible?

Modern bakery production lines are flexible due to the integration of smart technologies, which allow for real-time adjustments in production volumes and quick transitions between recipes and ingredients.

How do automation advancements enhance bakery customization?

Automation advancements enable bakeries to quickly adapt modular equipment for different recipes, allowing for personalized blends and flavors without significant downtime.

What are the benefits of artisan-style bread production at scale?

Artisan-style bread production at scale allows bakeries to maintain high quality and authentic flavors, appealing to consumer preferences for traditional techniques and high-quality ingredients.

How do modern methods enhance the production of croissants and Danish pastries?

Modern methods such as automated systems for laminating dough and automatic filling stations enhance production by ensuring consistent layering and efficient integration of fruit fillings, maintaining quality and appeal.

Why are automated systems essential for cake and muffin production?

Automated systems are crucial for ensuring consistent quality, precise portion control, and efficient production turnover, aligning with consumer demand for visually appealing and varied snack options.

How do bakeries maintain consistency in mass production of cookies and biscuits?

Precision technology and dedicated assembly lines allow bakeries to achieve uniformity in shape and size, manage efficient packaging, and ensure high-quality products.

Table of Contents

- The Flexibility of Modern Bakery Production Lines

- Essential Bread Varieties Produced at Scale

- Pastry Production: From Croissants to Danishes

- Cakes and Muffins: Automated Sweet Treats

- Cookies and Biscuits: Precision Mass Production

-

FAQ Section

- What makes modern bakery production lines flexible?

- How do automation advancements enhance bakery customization?

- What are the benefits of artisan-style bread production at scale?

- How do modern methods enhance the production of croissants and Danish pastries?

- Why are automated systems essential for cake and muffin production?

- How do bakeries maintain consistency in mass production of cookies and biscuits?