Commercial bakeries rely heavily on efficient equipment to maintain consistent quality and productivity. Among the most critical tools in any bakery operation are bread slicers, which transform loaves into uniform slices that customers expect. The right bread slicer can significantly impact your bakery's workflow, product presentation, and overall profitability. Selecting the appropriate equipment requires careful consideration of various factors including blade quality, slicing thickness options, and overall durability.

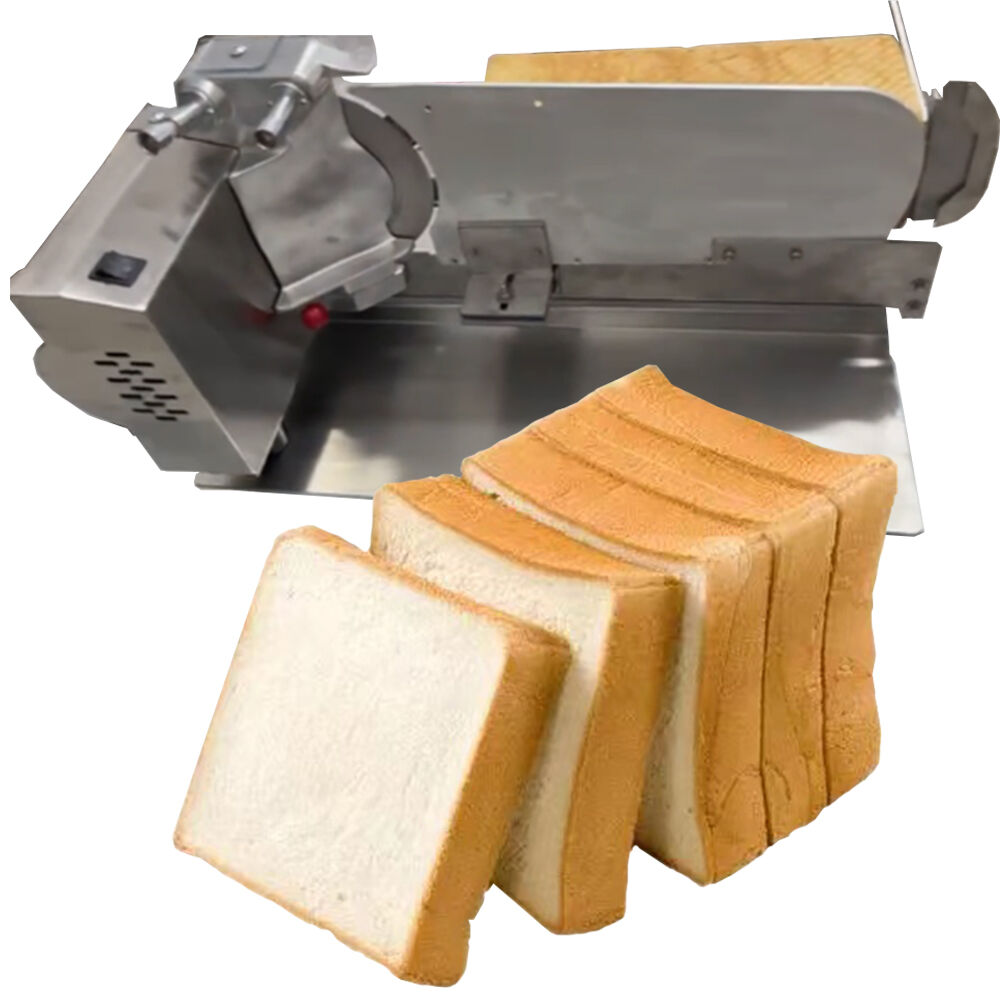

Understanding the different types of bread slicers available helps bakery owners make informed purchasing decisions. Manual bread slicers offer basic functionality for smaller operations, while automatic models provide higher throughput for busy commercial environments. The choice between these options depends on your bakery's daily production volume and budget constraints. Professional-grade equipment typically features stainless steel construction, adjustable slice thickness, and safety mechanisms to protect operators during use.

Types of Commercial Bread Slicers

Manual Bread Slicing Equipment

Manual bread slicers represent the most cost-effective entry point for smaller bakeries and specialty shops. These units require operators to guide loaves through the cutting mechanism manually, providing complete control over the slicing process. The construction typically features a sturdy base with integrated blade guards and adjustable thickness settings. While manual operation requires more labor, these bread slicers offer exceptional precision for artisan breads and specialty products that demand careful handling.

The advantages of manual bread slicers include lower initial investment costs, reduced maintenance requirements, and quiet operation suitable for customer-facing environments. Many bakeries appreciate the ability to customize each slice according to specific customer requests or product characteristics. Additionally, manual units consume no electricity, making them ideal for locations with limited power availability or operations seeking to minimize energy costs.

Automatic Bread Slicing Systems

Automatic bread slicers revolutionize high-volume bakery operations by eliminating manual labor and increasing throughput significantly. These sophisticated machines feature motorized feeding mechanisms that guide loaves through multiple razor-sharp blades simultaneously. The result is consistently uniform slices produced at remarkable speeds, often processing dozens of loaves per hour. Advanced models include programmable controls for different bread types and automated bagging systems for enhanced efficiency.

Investment in automatic bread slicers delivers substantial returns through increased productivity and reduced labor costs. These machines excel in high-volume production environments where consistency and speed are paramount. Safety features include emergency stops, blade guards, and automatic shut-off mechanisms to protect operators. Regular maintenance ensures optimal performance and extends equipment lifespan, making these units valuable long-term investments for growing bakeries.

Key Features to Consider

Blade Quality and Configuration

The blade system represents the heart of any bread slicer, directly impacting slice quality and equipment longevity. High-carbon steel blades maintain sharp edges longer than standard alternatives, reducing replacement frequency and maintenance costs. The number of blades determines slice thickness options, with professional bread slicers offering adjustable settings from thin sandwich slices to thick artisan cuts. Proper blade alignment ensures clean cuts without crushing or tearing delicate bread textures.

Blade replacement procedures vary significantly between different bread slicers, affecting long-term operational costs. Some models feature quick-release mechanisms for easy blade changes, while others require disassembly for maintenance. Consider the availability of replacement blades and associated costs when evaluating different options. Quality blade systems also include safety features such as guards and locking mechanisms to prevent accidental contact during operation or maintenance.

Construction Materials and Durability

Commercial-grade bread slicers must withstand constant use in demanding bakery environments. Stainless steel construction offers superior corrosion resistance and easy cleaning, essential requirements for food service equipment. Heavy-duty frames provide stability during operation, preventing vibration that could affect slice quality. Look for reinforced mounting points and solid construction that can handle the repetitive stresses of commercial operation without premature wear.

Surface finishes play crucial roles in hygiene and maintenance efficiency. Smooth, non-porous surfaces resist bacterial growth and facilitate thorough cleaning between production runs. Some bread slicers feature removable components for deep cleaning, while others include integrated cleaning systems. Evaluate the ease of disassembly and reassembly when considering different models, as this directly impacts daily maintenance requirements and operational efficiency.

Sizing and Capacity Considerations

Determining Production Volume Requirements

Accurate assessment of your bakery's daily production volume guides appropriate bread slicer selection. Small artisan bakeries producing 50-100 loaves daily have different requirements than large commercial operations processing thousands of units. Consider peak production periods when calculating capacity needs, as equipment must handle maximum loads without compromising quality or safety. Factor in future growth projections to avoid premature equipment replacement as your business expands.

Production scheduling affects bread slicer utilization patterns and capacity requirements. Bakeries with concentrated morning production rushes need higher-capacity equipment than operations with steady throughout-the-day processing. Evaluate your current workflow patterns and identify bottlenecks that appropriate bread slicers could resolve. Consider whether multiple smaller units or one large capacity machine better suits your operational needs and space constraints.

Space and Installation Requirements

Physical space limitations significantly influence bread slicer selection in many bakery environments. Measure available floor space, accounting for operator movement and safety clearances around equipment. Consider ceiling height restrictions for taller models and ensure adequate ventilation for enclosed installation areas. Some bread slicers require dedicated electrical circuits or specific power configurations that may necessitate facility modifications.

Installation requirements vary considerably between different bread slicers, affecting total project costs. Some units arrive ready for immediate use, while others require professional installation and calibration. Consider proximity to existing power sources, waste disposal systems, and cleaning stations when planning equipment placement. Proper installation ensures optimal performance and extends equipment lifespan while maintaining safety standards.

Safety Features and Compliance

Operator Protection Systems

Modern bread slicers incorporate numerous safety features designed to protect operators from injury during routine use. Blade guards prevent accidental contact with cutting surfaces, while emergency stop mechanisms allow immediate equipment shutdown in dangerous situations. Interlock systems prevent operation when safety covers are removed, ensuring proper configuration before each use. Look for units with clear safety labeling and intuitive control layouts that minimize operator confusion.

Training requirements for safe operation vary between different bread slicers, affecting staffing considerations and ongoing costs. Simple manual units require basic instruction, while complex automatic systems may need comprehensive training programs. Consider the learning curve associated with different models and evaluate whether your staff can adapt quickly to new equipment. Proper training reduces accident risk and ensures optimal equipment utilization throughout its operational life.

Regulatory Compliance Standards

Food service equipment must meet stringent regulatory standards for commercial use in most jurisdictions. Verify that prospective bread slicers carry appropriate certifications from recognized testing organizations. NSF International certification indicates compliance with food safety and sanitation requirements, while UL listings confirm electrical safety standards. Some regions have additional requirements that may affect equipment selection and installation procedures.

Compliance documentation facilitates health department inspections and insurance requirements for commercial bakeries. Maintain complete records of equipment certifications, installation procedures, and ongoing maintenance activities. Some bread slicers include compliance documentation packages that simplify regulatory approval processes. Consider the availability of technical support and documentation when evaluating different manufacturers and models.

Maintenance and Operating Costs

Routine Maintenance Requirements

Regular maintenance ensures optimal performance and extends the operational life of bread slicers significantly. Daily cleaning procedures remove flour residue and prevent bacterial growth that could contaminate products. Weekly maintenance typically includes blade inspection, lubrication of moving parts, and calibration verification. Establish maintenance schedules based on manufacturer recommendations and usage patterns to prevent premature wear and costly repairs.

Preventive maintenance programs reduce unexpected downtime and repair costs associated with bread slicers. Document all maintenance activities to identify patterns and optimize scheduling efficiency. Some manufacturers offer maintenance contracts that include regular service visits and emergency repair coverage. Consider the availability of local service technicians when evaluating different brands and models, as prompt repair service minimizes production disruptions.

Long-term Operating Expenses

Total cost of ownership extends far beyond initial purchase price for commercial bread slicers. Energy consumption varies significantly between different models, affecting monthly utility costs throughout equipment life. Factor in blade replacement costs, which can be substantial for high-volume operations processing hundreds of loaves daily. Some units feature energy-efficient motors and standby modes that reduce operating costs without sacrificing performance.

Replacement parts availability and pricing significantly impact long-term ownership costs for bread slicers. Established manufacturers typically maintain parts inventories longer than smaller companies, ensuring continued support throughout equipment life. Consider warranty coverage and extended service plans when calculating total ownership costs. Some suppliers offer comprehensive packages that include training, maintenance, and parts coverage for predictable annual expenses.

Frequently Asked Questions

What slice thickness options should commercial bread slicers offer?

Professional bread slicers should provide adjustable thickness settings ranging from 3/8 inch for thin sandwich slices to 1 inch for thick artisan cuts. The most versatile units offer infinite adjustment within this range, allowing customization for different bread types and customer preferences. Some models include preset positions for common slice thicknesses, speeding operation and ensuring consistency between different operators.

How often do bread slicer blades need replacement?

Blade replacement frequency depends on usage volume and bread types processed through the equipment. High-volume operations may require new blades every 2-3 months, while smaller bakeries might extend replacement intervals to 6 months or longer. Dense or crusty breads wear blades faster than soft sandwich loaves. Regular inspection helps identify when blades become dull and begin affecting slice quality, indicating replacement time.

Can bread slicers handle different types of baked goods?

Most commercial bread slicers are designed specifically for standard bread loaves and may not accommodate other baked goods effectively. Bagels, rolls, and irregularly shaped items typically require specialized slicing equipment. However, some versatile units include adjustable guides and supports that can handle various product shapes and sizes. Consider your complete product line when selecting bread slicers to ensure compatibility with all items requiring slicing.

What power requirements do commercial bread slicers need?

Manual bread slicers require no electrical power, while automatic models typically need standard 110-120V single-phase power for smaller units or 220-240V for high-capacity equipment. Some large industrial bread slicers may require three-phase power connections. Verify your facility's electrical capacity matches equipment requirements before purchase, as upgrades can add significant installation costs to your project budget.