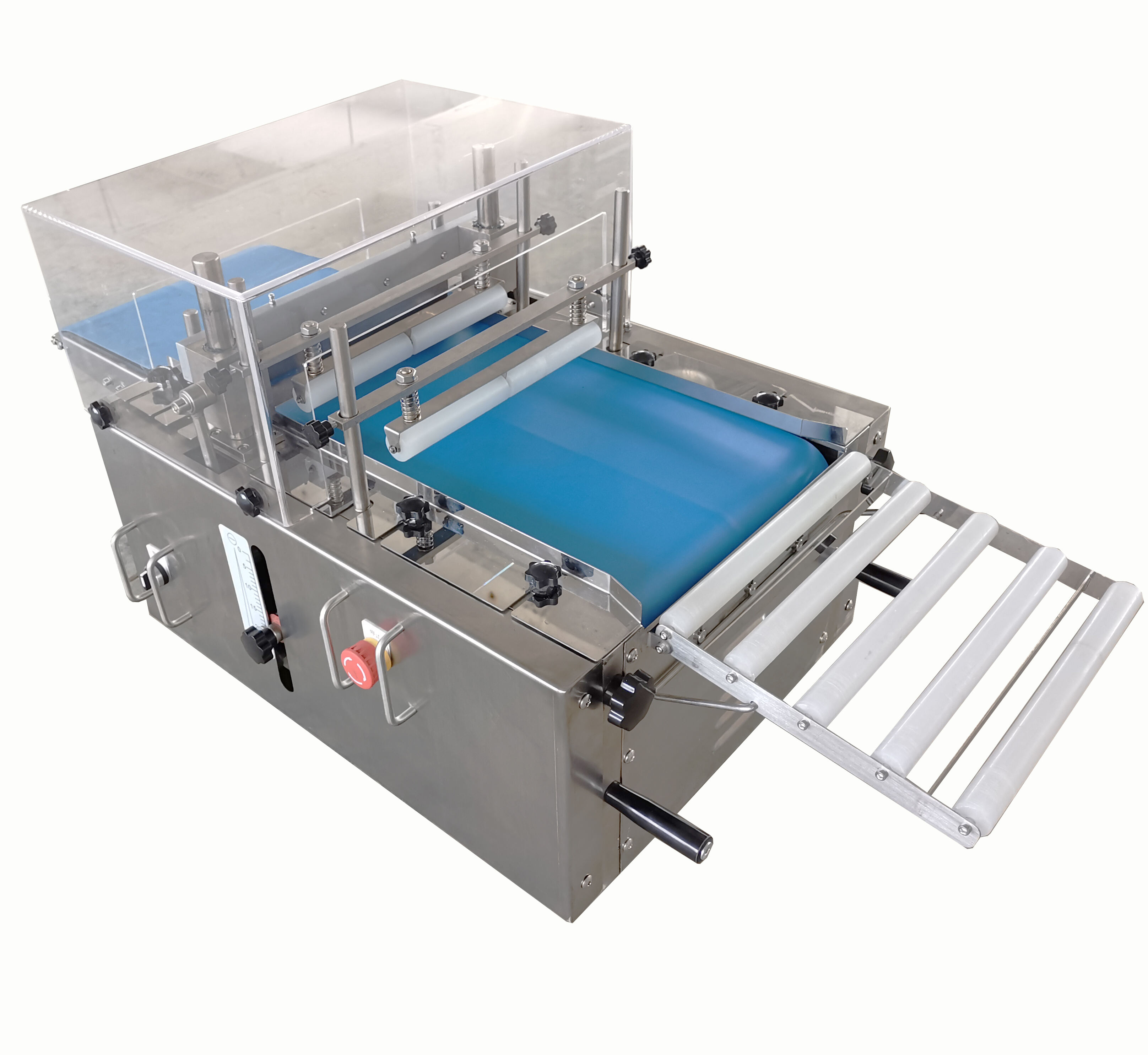

индустриална машина за правене на хляб

Индустриалната машина за правене на хляб представлява ключов елемент на съвременните комерциални пекарски операции, комбинирайки напреднала технология с прецизно инженерство, за да доставя последователни, висококачествени хлябопродукти в големи мащаби. Тези sofisticirani системи включват множество етапи от процеса за правене на хляб, от смесването на съставките и развитието на тестото до ферментацията и печенето, всичко в рамките на един автоматизиран линей. Интелигентната контролна система на машината поддържа прецизни нива на температурата и влажността през всеки етап, гарантирайки оптимално развитие на тестото и идеални условия за печене. При производствени капацитети, които се движат между 500 и 5000 бурека на час, тези машини разполагат с конструкция от неръжавееща стомана, енергоефективни системи за отопление и програмируеми контроли, които позволяват различни стилове на хляб и рецепти. Смесителната камера използва специализирани конфигурации на лези, за да постигне идеалното развитие на глютен, докато камерата за ферментация създава перфектната среда за ферментация на мая. Напредните конвеири транспортират тестото през всеки етап с минимално човешко намесване, намалявайки разходите за работа и поддържайки последователно качество на продукта. Безопасностните функции включват бутони за аварийна спирачка, защита от прекарични натоварвания и системи за мониторинг на температурата, гарантирайки надеждно функциониране в комерциални околнosti. Модуларният дизайн облеснява техническото обслужване и чистенето, докато цифровите интерфейси позволяват на операторите да мониторят и да регулират параметрите в реално време, правейки тези машини основни за индустриалното производство на хляб.