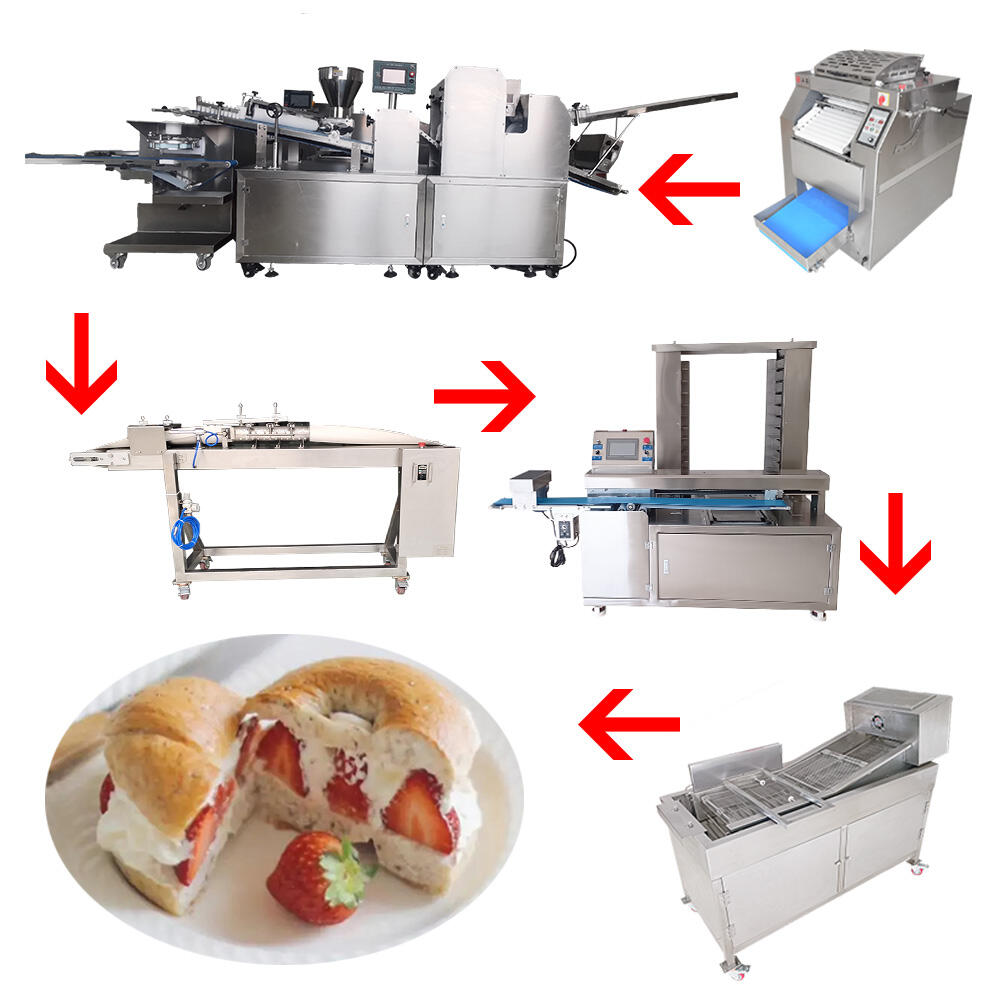

автоматичен сече бейгли

Автоматичният сечер за бейгли представлява значителен напредък в оборудването за комерсиални и домашни кухни, предлагайки безопасно и ефективно решение за идеално насечени бейгли всеки път. Това иновативно устройство разполага с прецизно проектирани лезия, които постоянно режат бейглите на две равни половинки, без да ги притискат или рвут нежната текстура. Дизайнът му, насочен към безопасността, включва защитни ограждания и функции за автоматично изключване, които предотвратяват случайни увечия по време на операцията. Построен от дюраствено неръжавеещо стоманено оборудване, автоматичният сечер за бейгли поддържа различни размери и видове бейгли, от традиционните просто до семенни варианти. Неговото компактно място го прави идеален както за заетите комерсиални кухни, така и за домашни работни повърхности, докато потребителят може да започне да го използва след минимално обучение. Устройството разполага с регулируеми настройки за дебелина на сеченията, които позволяват на потребителите да персонализират сеченията според своите предпочитания. По-продвинатите модели предлагат антибактериални повърхности и лесно очистими компоненти, които поддържат стандартите на чистота в околната среда за хранителни услуги. Автоматичният механизъм за подаване гарантира последователни резултати, като защитава ръцете на операторите от режещото лезие, което го прави основен инструмент за магазини за бейгли, кафе и домакинства, които ценят както безопасността, така и ефективността.