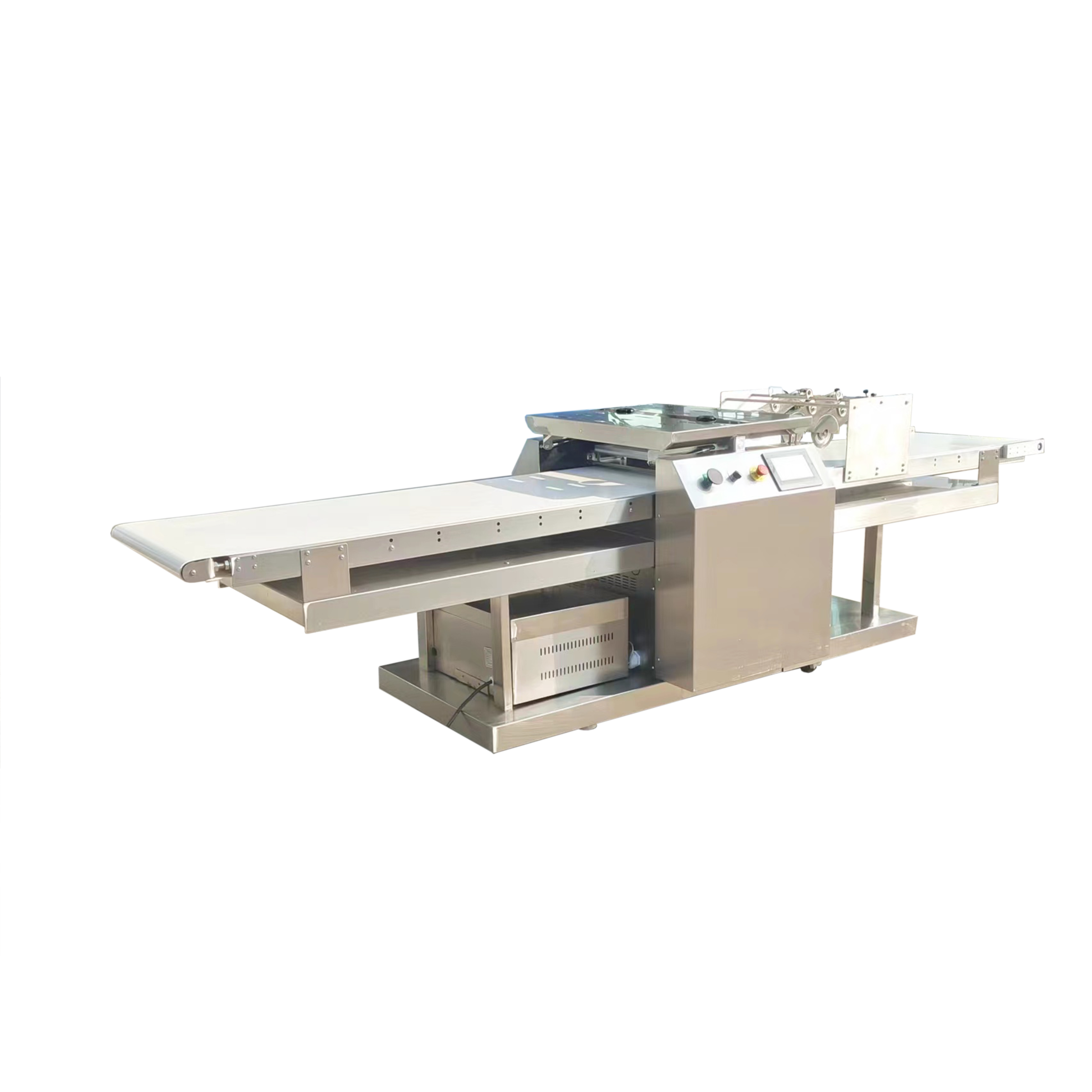

toast cutting machine

The toast cutting machine represents a revolutionary advancement in bakery automation technology, designed to efficiently and precisely slice toast bread into uniform pieces. This sophisticated equipment combines precision engineering with user-friendly operation, featuring adjustable thickness settings ranging from 8mm to 30mm to accommodate various product specifications. The machine incorporates a high-grade stainless steel blade system that ensures clean, consistent cuts while maintaining the structural integrity of each slice. Operating at speeds of up to 40 loaves per minute, it significantly enhances production efficiency while reducing waste and labor costs. The machine is equipped with advanced safety features, including automatic shut-off mechanisms and protective guards, ensuring operator safety throughout the cutting process. Its compact design optimizes floor space utilization while maintaining high output capabilities, making it ideal for both industrial bakeries and smaller commercial operations. The toast cutting machine also features an innovative crumb collection system that maintains a clean working environment and facilitates easy maintenance. With its programmable interface, operators can easily adjust settings to accommodate different bread types and sizes, ensuring versatility across various production requirements.