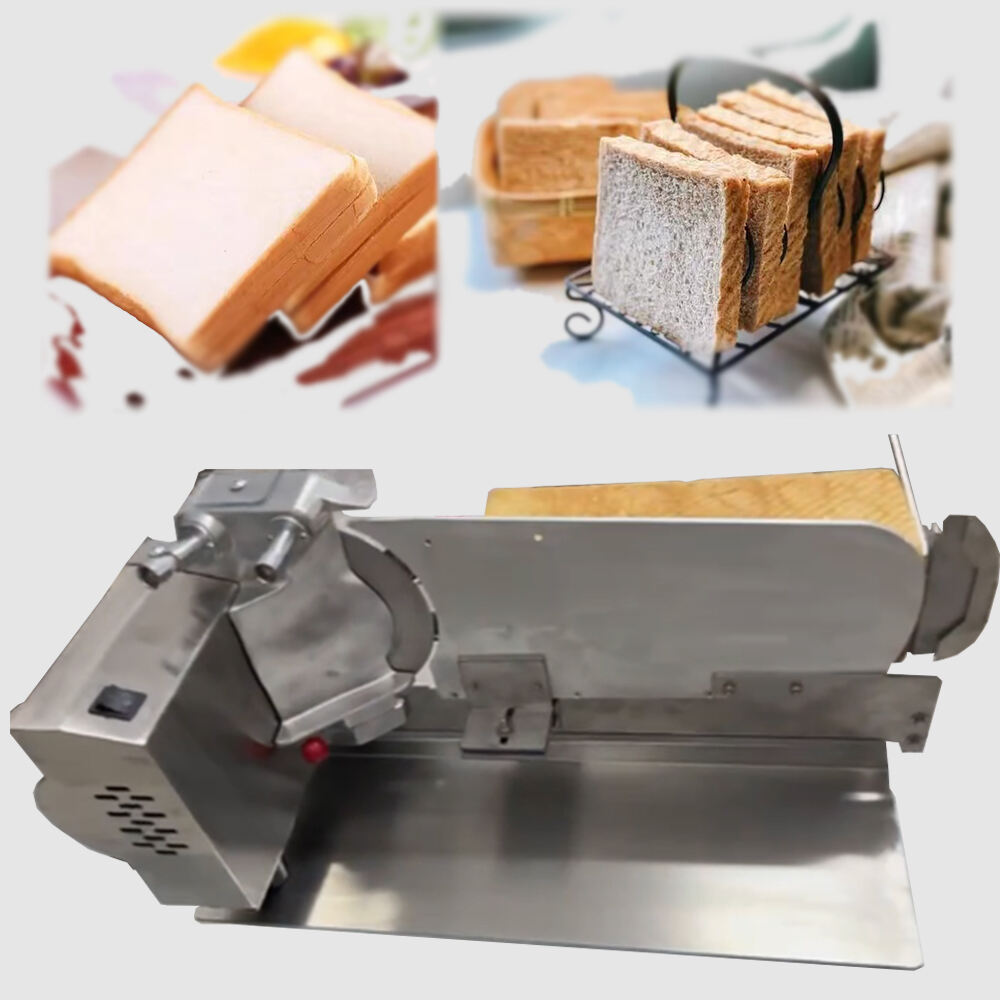

commercial bread slicer machine

A commercial bread slicer machine is an essential piece of equipment designed to efficiently and precisely slice various types of bread products in professional food service settings. This sophisticated machinery combines precision engineering with user-friendly operation to deliver consistent, uniform slices that meet commercial standards. The machine typically features adjustable slice thickness settings, ranging from thin sandwich slices to thicker artisanal cuts, accommodating different bread types and customer preferences. Modern commercial bread slicers incorporate safety features including blade guards and emergency stop buttons, ensuring operator protection while maintaining high productivity. These machines are constructed with durable materials like stainless steel and food-grade plastics, making them suitable for continuous operation in busy bakeries, restaurants, and food processing facilities. The cutting mechanism usually consists of multiple parallel blades that simultaneously slice entire loaves, dramatically reducing processing time compared to manual slicing. Advanced models often include features such as automatic loaf positioning systems, crumb collection trays, and quiet operation technology, making them ideal for both front-of-house and kitchen environments.