bread slicers

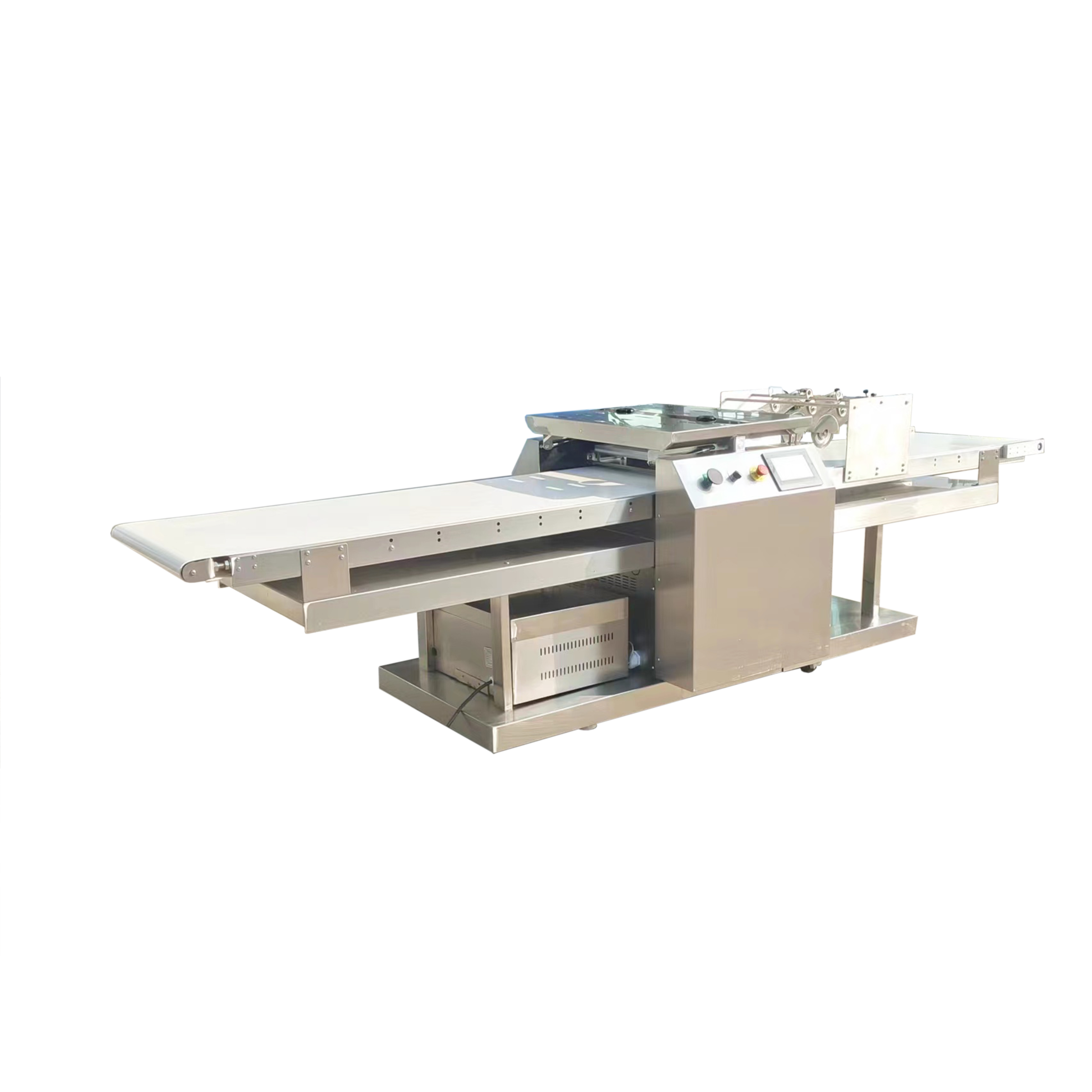

Bread slicers represent an essential piece of equipment in both commercial and home kitchens, designed to transform whole loaves into perfectly uniform slices with precision and efficiency. These innovative machines combine mechanical engineering with practical functionality, featuring adjustable slice thickness settings typically ranging from 1/4 inch to 1 inch, allowing users to customize cuts according to their specific needs. Modern bread slicers incorporate high-grade stainless steel blades, positioned in parallel configurations to ensure clean, consistent cuts without crushing or tearing the bread. The machines often include safety features such as blade guards and automatic shut-off mechanisms, protecting users during operation. Advanced models feature digital controls for precise thickness adjustment and slice counting capabilities, beneficial for commercial operations tracking production volumes. These slicers accommodate various bread types, from soft sandwich loaves to crusty artisanal bread, with specialized guide channels that maintain stability during cutting. The equipment's design typically emphasizes easy cleaning and maintenance, with removable crumb trays and dishwasher-safe components, ensuring optimal hygiene standards and prolonged operational life.