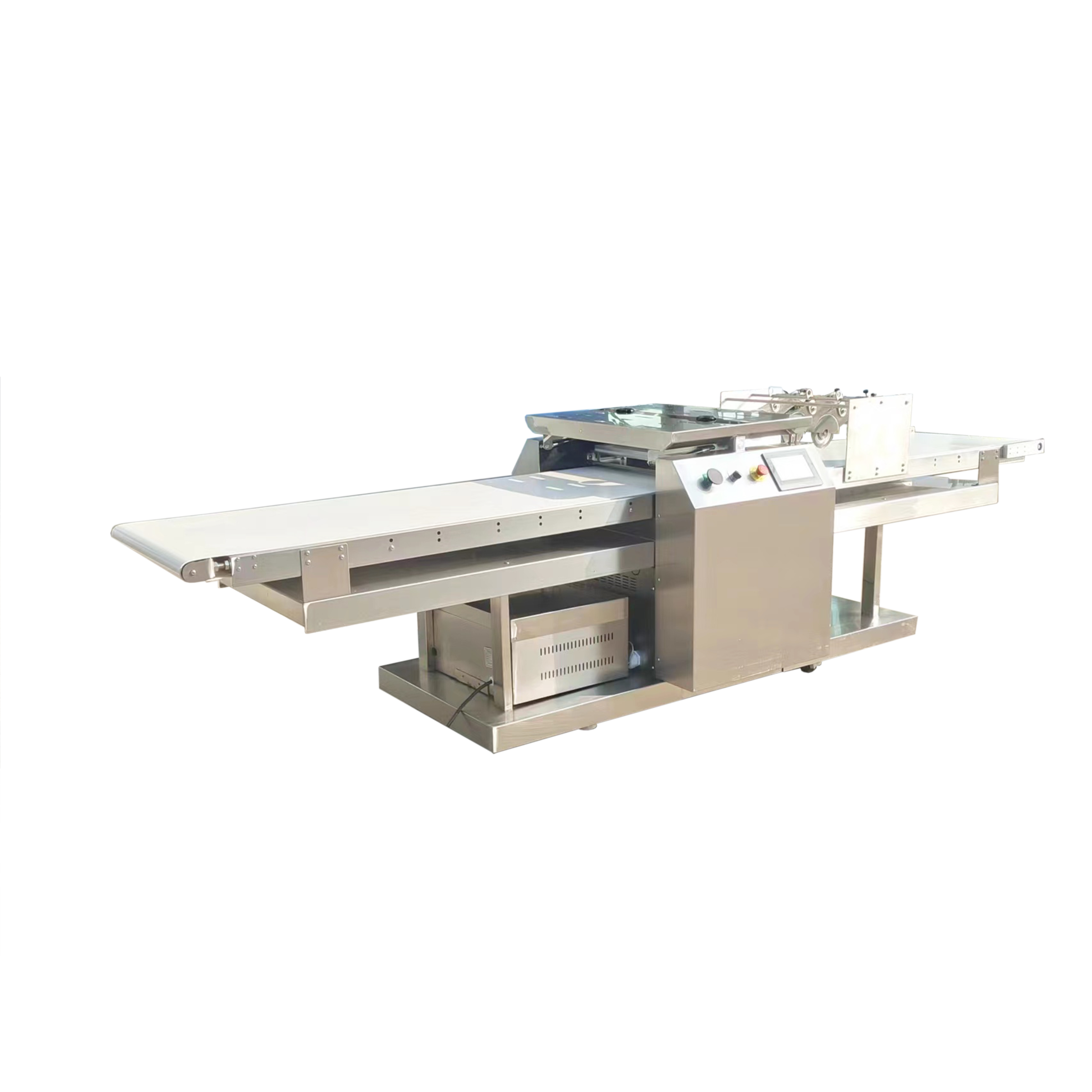

bread slicer machine

The bread slicer machine represents a revolutionary advancement in commercial and industrial bakery operations, offering precise and consistent slicing capabilities for various types of bread products. This sophisticated equipment combines mechanical precision with user-friendly operation, featuring adjustable slice thickness settings typically ranging from 8mm to 25mm. The machine utilizes high-quality stainless steel blades arranged in a parallel configuration, ensuring clean cuts without crushing or tearing the bread structure. Modern bread slicers incorporate safety features such as automatic shut-off mechanisms and protective guards, prioritizing operator safety while maintaining optimal performance. The machine's frame is constructed from durable materials, often featuring a combination of stainless steel and food-grade plastics, ensuring longevity and easy cleaning. Advanced models include features such as digital controls, speed adjustments, and automatic loaf positioning systems, enabling efficient processing of different bread sizes and types. These machines can handle various bread products, from soft sandwich loaves to crusty artisanal breads, maintaining consistent slice thickness and quality throughout operation. The design typically includes crumb collection systems and easy-access panels for maintenance, making it both practical and hygienic for commercial use.