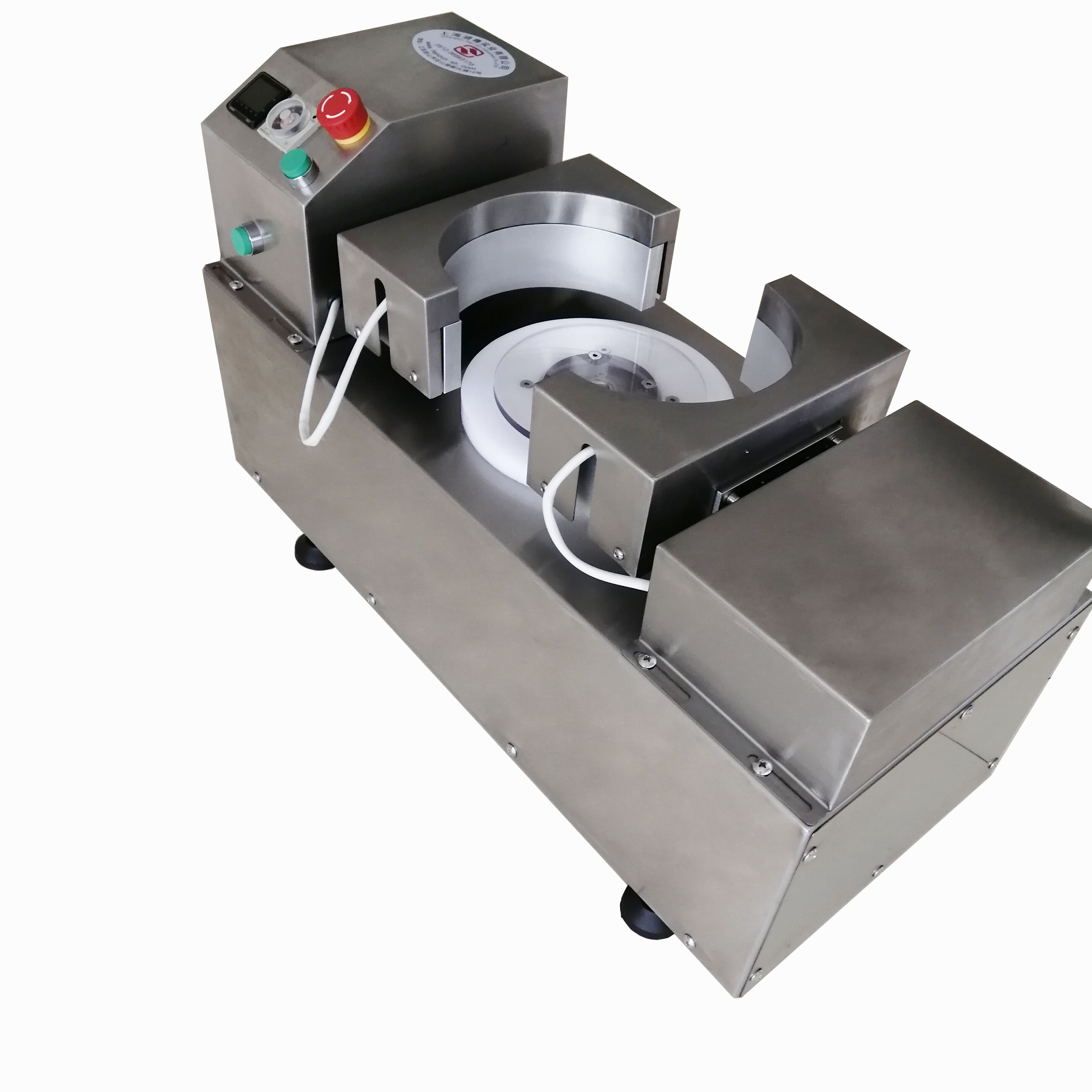

bread cutting machine

The bread cutting machine represents a revolutionary advancement in commercial and industrial bakery operations. This precision-engineered equipment efficiently transforms whole loaves into uniformly sliced bread with exceptional accuracy and speed. Operating through a sophisticated system of parallel blades, the machine accommodates various bread types, from soft sandwich loaves to artisanal crusty breads. The cutting mechanism features adjustable blade spacing, allowing operators to customize slice thickness according to specific requirements. Advanced safety features include automatic shut-off systems and protective guards ensuring operator safety while maintaining optimal performance. The machine's stainless steel construction guarantees durability and easy cleaning, meeting strict hygiene standards essential for food processing equipment. Modern bread slicers incorporate digital controls for precise operation and maintenance monitoring, while their compact design maximizes workspace efficiency. The equipment's high-capacity feed system can process multiple loaves simultaneously, significantly increasing productivity. Additionally, these machines often feature catch trays and bagging stations, streamlining the packaging process and maintaining product freshness. With minimal maintenance requirements and long-term reliability, bread cutting machines have become indispensable tools in modern bakery operations.