bakery machinery

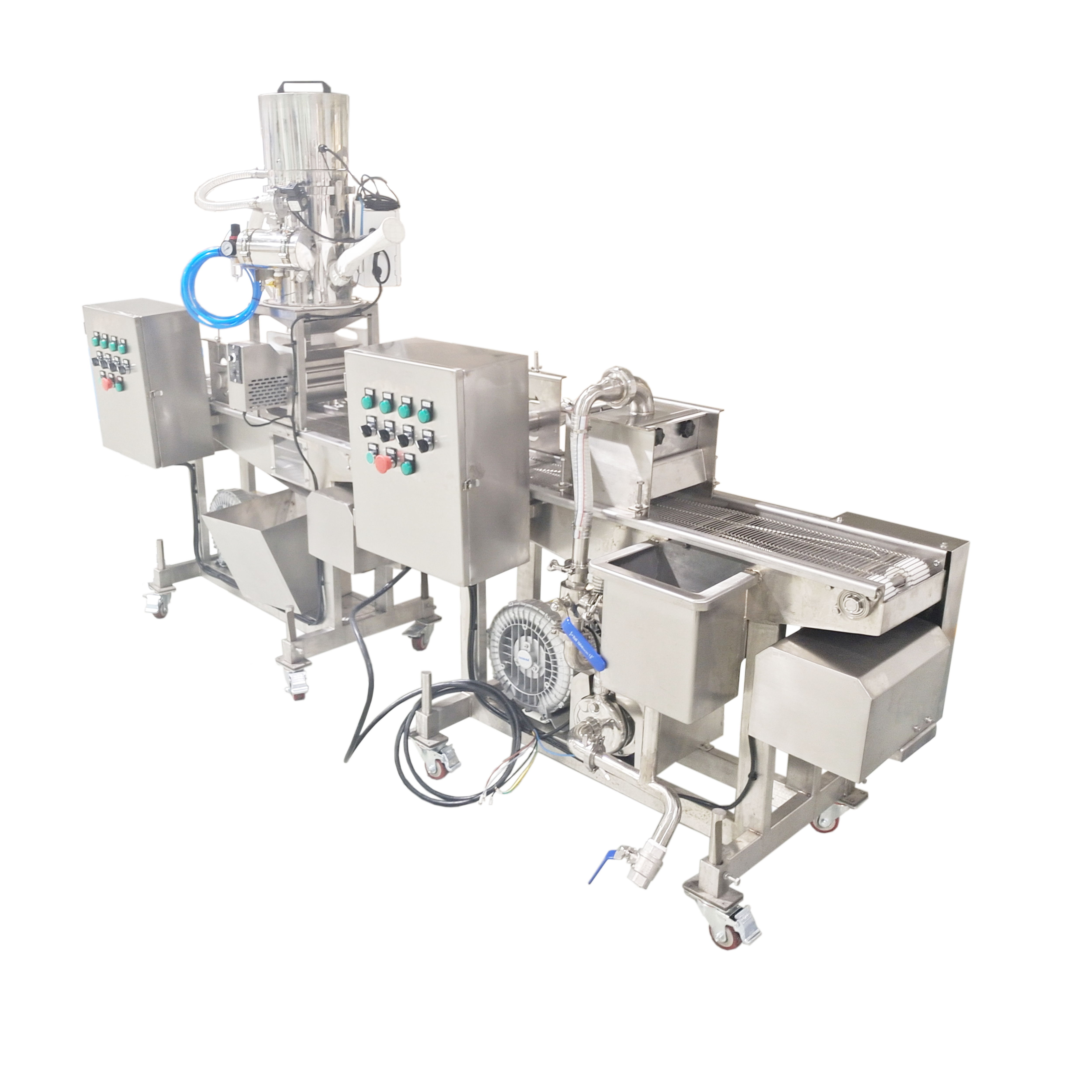

Bakery machinery represents a comprehensive suite of equipment designed to streamline and enhance commercial baking operations. These sophisticated systems integrate multiple functions, from dough mixing and shaping to precise temperature control and automated baking processes. Modern bakery machinery incorporates advanced features such as digital control panels, programmable recipes, and energy-efficient operations. The equipment typically includes industrial mixers capable of handling large batches, automated dough dividers and rounders, proofing chambers with humidity control, and conveyor-belt ovens that ensure consistent baking results. These machines are engineered to maintain precise tolerances in dough preparation, ensuring product consistency while significantly reducing manual labor. The machinery's versatility allows for the production of various baked goods, from artisanal bread to mass-produced pastries, while maintaining high quality standards. Safety features such as emergency shut-offs, thermal protection, and guard rails are integrated into the design, ensuring operator safety without compromising productivity. The equipment is constructed from food-grade materials, typically stainless steel, making it durable and easy to clean while meeting strict hygiene regulations.