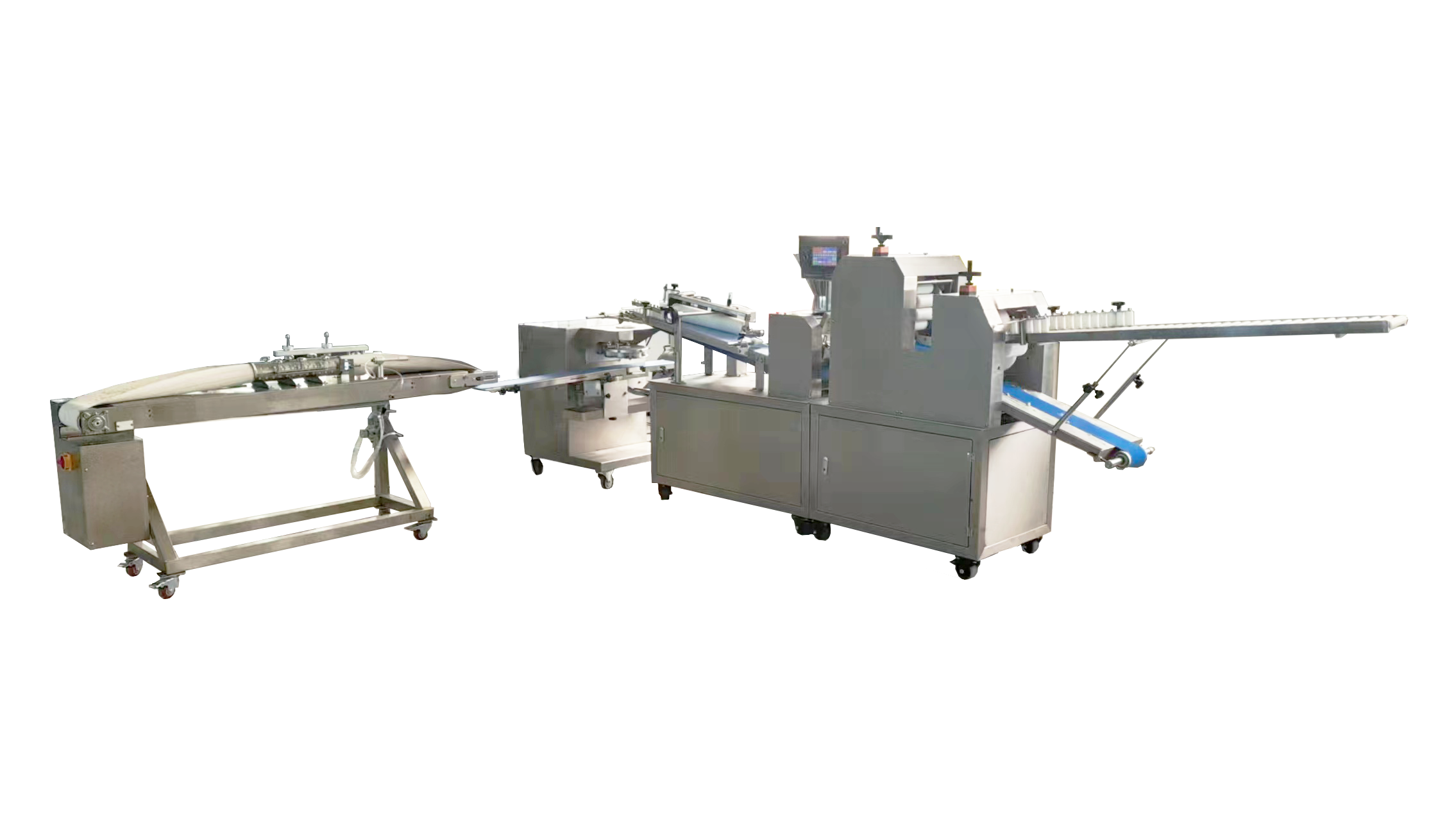

instrumentum commerciale pro anulis panis

Instrumenta bagel commericialia machinamenta essentialia significant, specialiter ad productionem magni voluminis bagel in panificiis, coenobiis et institutis cibariis descripta. Haec systemata peritialem plerumque componentes tales ut mixtiones, dividentes, volventes, formantes, probationes et fornaces industriales continent, omnia simul operantia ad processum conficiendi bagel optimo modo dirigendum. Instrumenta facultates miscendi automatisatas praebent, consistentem texturam et qualitatem certam dum magnas fasciculos efficienter tractant. Systemata moderna faciendi bagel temperaturam accurate controlant, dispositiones programmabiles et mecanismos formandi praecipuos quod sigillum formae bagel cum constantia mirifica creat. Machina ingeniose facta est ad technicas traditionales faciendi bagel conservandas dum capacitem productionis magnopere augens, centenas usque ad milia bagel per horam producere potest. Haec systemata saepe formas energetice efficiens, constructionem durabilem ex aere argenteo et interfaces amicales usui quae operationem et conservationem simplificant continent. Instrumenta saepius inclyta munia continebunt, tales ut clausulas emergentium clausurarum, railes custodiae et protectiones thermale, operatoris tutores durante productione.