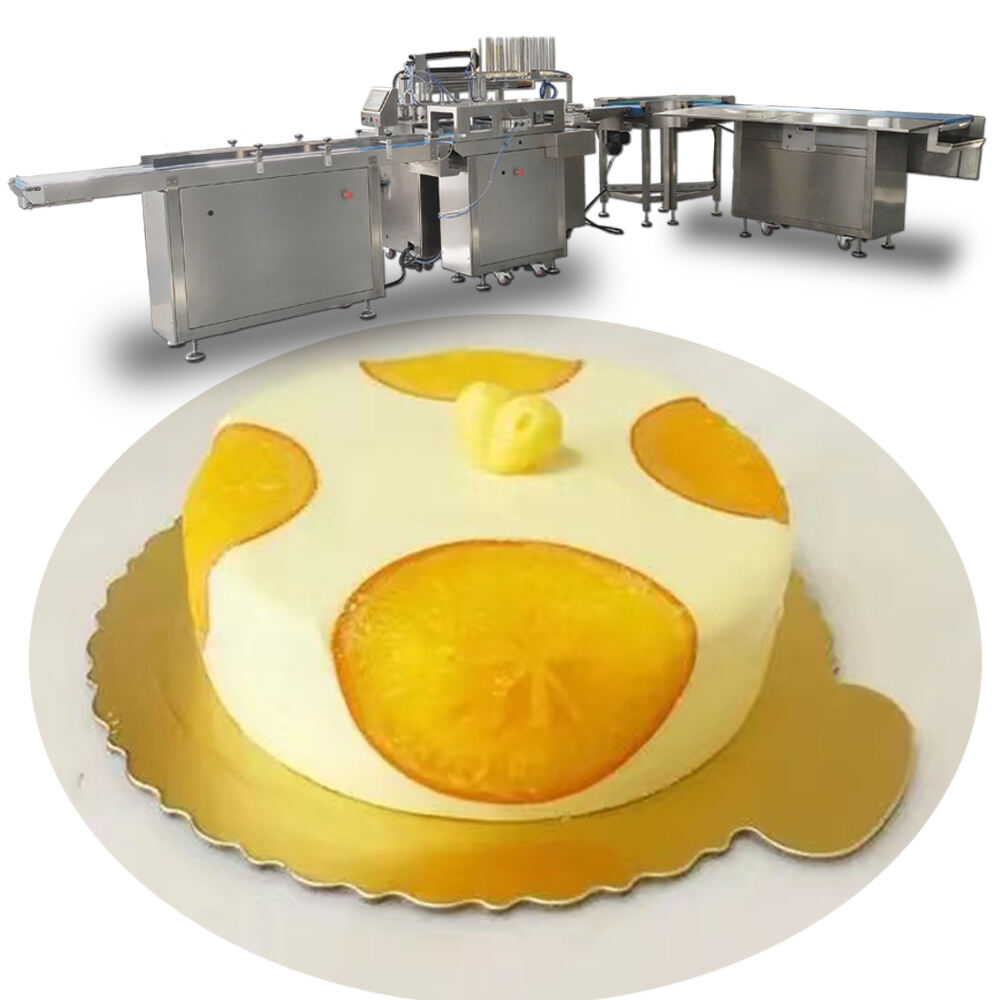

commercial bakery equipment

Commercial bakery equipment represents the backbone of modern professional baking operations, encompassing a comprehensive range of specialized machinery designed to streamline and enhance the baking process. These sophisticated systems include industrial mixers capable of handling large batches of dough, professional-grade ovens with precise temperature control and multiple baking chambers, automated dough dividers and rounders for consistent portioning, and advanced proofing systems that maintain optimal temperature and humidity levels. The equipment features state-of-the-art digital controls, enabling precise parameter adjustments and programming capabilities for various recipes. Modern commercial bakery equipment often incorporates energy-efficient technologies, reducing operational costs while maintaining superior baking results. These systems are engineered with food safety in mind, featuring stainless steel construction and easy-to-clean surfaces that comply with industry hygiene standards. The equipment's modular design allows for seamless integration into existing production lines, while smart connectivity features enable real-time monitoring and production data analysis. From small artisanal bakeries to large-scale industrial operations, these machines are scalable to meet diverse production needs, offering versatility in product types and quantities.